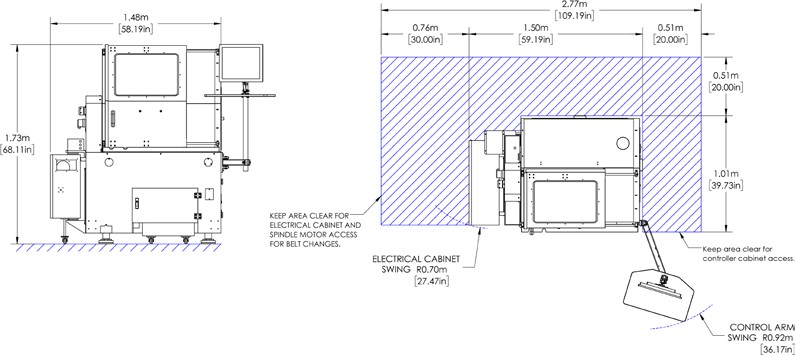

Location

The area should be well lit, dry, have proper ventilation, provide for unobstructed machine motion and operation, and ensure unrestricted access to all lathe controls and the electrical cabinet.

Electrical Requirements

Primary: 200-250 VAC, 50/60 Hz at 20 Amps

NOTE: Continuous current is below 15 Amps, but requires a 20 Amp breaker or slow blow fuse to prevent nuisance trips of the circuit breaker on spindle start.

Either use a NEMA L6-20 plug, or hard wire the machine. A certified electrician must make all electrical connections, and it’s your responsibility to verify that the electrical installation of the machine meets all local regulations and electrical codes.

Secondary: Separate wall outlet of 115 VAC, 50/60 Hz at 15 Amps

A separate wall outlet of 115 VAC at 15 Amps is required to act as power source for the controller, monitor, and coolant pump. This connection is made to the IEC power inlet at the rear of the electrical cabinet.

For non-conforming sites:

-

Replace the stock coolant pump with a 230 VAC compatible pump (Hi-Quality 1/8 HP Coolant Pump Upgrade Kit, PN 33216), and change the Voltage Setting Switch on the controller to 230 VAC.

-

Use a step down transformer to convert 230 VAC to 110 VAC (Step-Up/Step-Down Transformer, PN 32009).

Electrical Noise

Both primary and secondary power should be provided by dedicated circuits. At the minimum, circuits should be isolated from electrically-noisy devices. In particular, high-inductive loads from units like vacuum cleaners or air compressors can be troublesome and/or cause controller malfunction. For non-conforming sites, refer to electrical requirement table earlier in this section.

Grounding

All power inputs to the lathe must be properly grounded. Check continuity between bare metal on machine frame and true earth ground (water pipe or similar) to ensure proper grounding.

Ground Fault Interrupter (GFI) Use

Primary power should not be protected by a ground fault interrupter (GFI) or residual current circuit breaker (RCCB), as this interferes with proper operation of the lathe’s variable frequency drive (VFD) spindle controller.

A GFI or RCCB must be used to supply power to the secondary 115 VAC power supply. The controller, monitor, and coolant system are not bolted to the machine frame so proper grounding cannot be assumed. The combination of electrical power and water-based coolant systems makes GFI protection for the 115 VAC circuit very important.

Looking for more information?

This is a section of the 15L operator's manual. To view the whole manual, go to Tormach document UM10225.

If you have additional questions, we can help. Create a support ticket with Tormach Technical Support at tormach.com/how-to-submit-a-support-ticket for guidance on how to proceed.