Getting your CNC lathe properly configured is essential for accurate and efficient turning. In this first installment of our 3-part series, we’ll walk through how to set up tool heights and lengths on the Tormach 8L Lathe. These steps are fundamental to achieving precision cuts and avoiding common errors in your turning operations.

Gathering Tools and Holders for the 8L Lathe

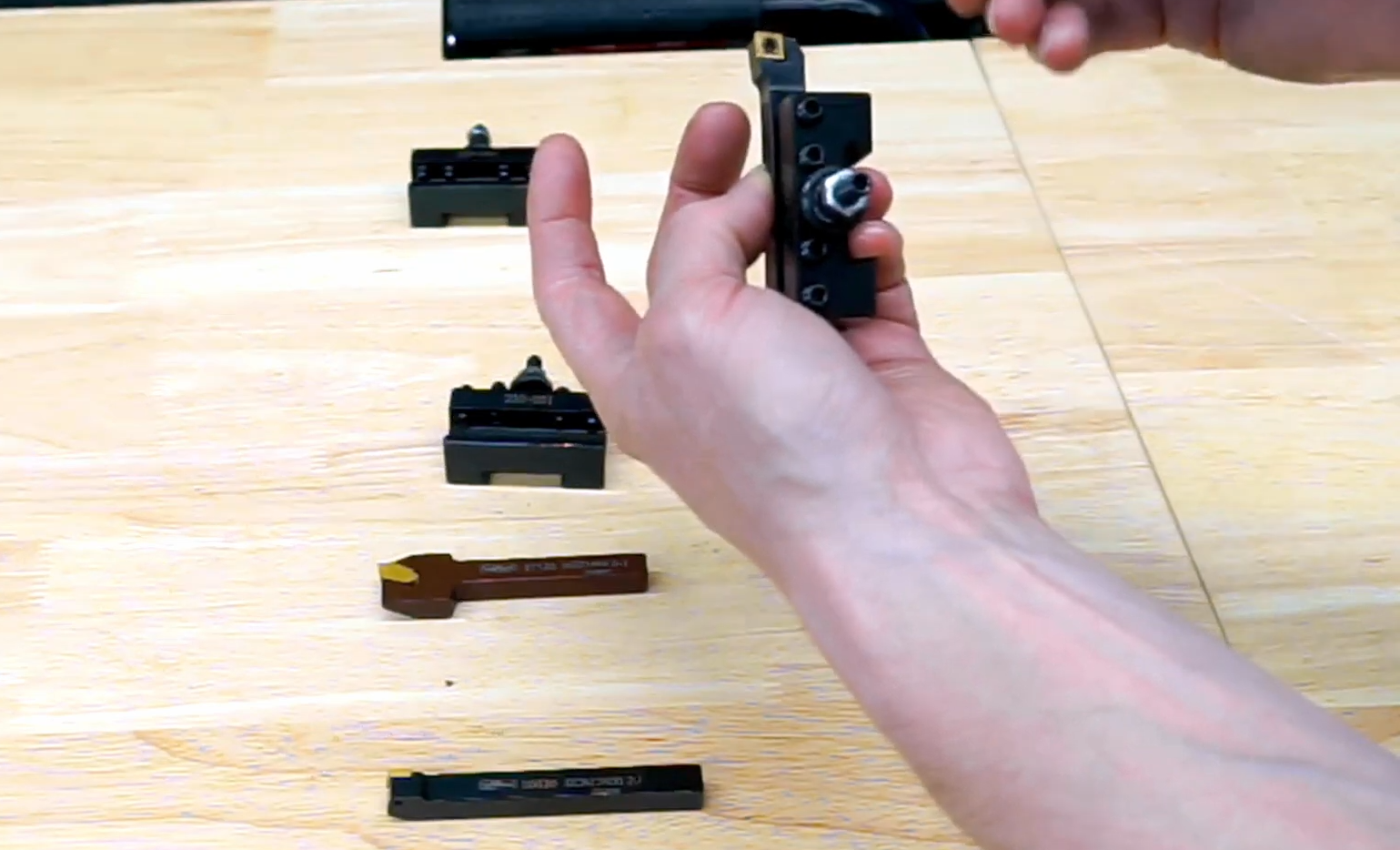

To begin, you’ll need tools from the Tormach Professional Lathe Tool Kit. In this setup, we are using tools with part numbers 35636, 35634, and 37128. You’ll also need tool holders, such as part number 30705. These holders allow you to mount your turning tools securely in the 8L’s quick-change tool post.

Start by loosening the four bolts on your tool holder. This will allow you to insert your tool into the holder. Slide the tool in so there’s minimal space between the holder and the cutting edge. Keeping the tool close to the holder reduces the chance of chatter and vibration during cutting.

Securing the Cutting Tool Properly On The 8L LATHE

Proper orientation of the cutting tool is critical. Make sure the cutting edge is facing the tool holder bolt, and that the insert is facing upward. This ensures the tool is positioned correctly for cutting on the lathe.

Once in place, tighten the bolts just enough to hold the tool while you align it. Ensure there is no visible gap between the tool and holder and that everything is squared up. Then go back and tighten the bolts fully. Start with the two outer bolts, followed by the inner ones. This staggered tightening pattern helps apply even pressure across the tool holder. Be sure the bolts are very tight, but not to the point of stripping them.

Why Tool Height and Length Matter on the Tormach 8L

Just as with a three-axis CNC mill, accurate tool height and length setup is essential when operating the 8L lathe. PathPilot®, Tormach’s control software, tracks these offsets for each tool, ensuring consistency during tool changes. Each tool and holder combination will vary slightly in length, so it’s important to record and calibrate these differences within the system.

In the next installment, we’ll cover how to measure and input tool offsets into PathPilot. This process ensures your 8L lathe runs with maximum accuracy and efficiency.