Low Air Pressure or Malfunctioning Air Pressure Switch - PCNC 1100

Background

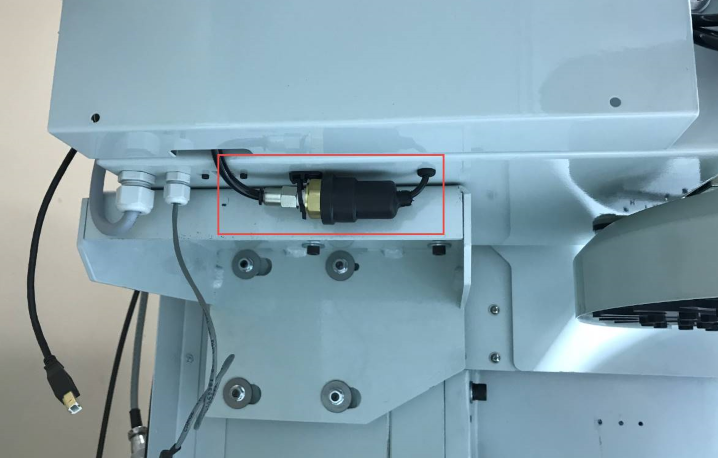

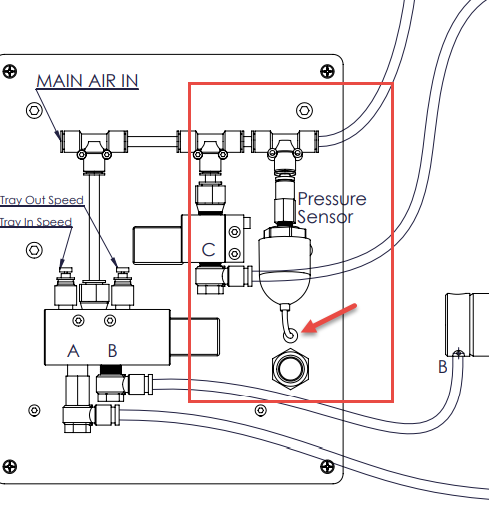

The pressure switch is a normally closed (low air pressure) switch that connects via a 3.5 mm jack into the back of the mounting plate on Legacy ATC’s. On the M style tool changers, they are located on the underside of the ATC electrical box, and are connected with two wire leads directly to the ATC board. When the switch has above 90 PSI it opens. The ATC control board looks for this open signal to indicate there is adequate air pressure.

M ATC

Legacy ATC

Disconnect and/or Replace the Sensor

Reason: The air pressure sensor is faulty.

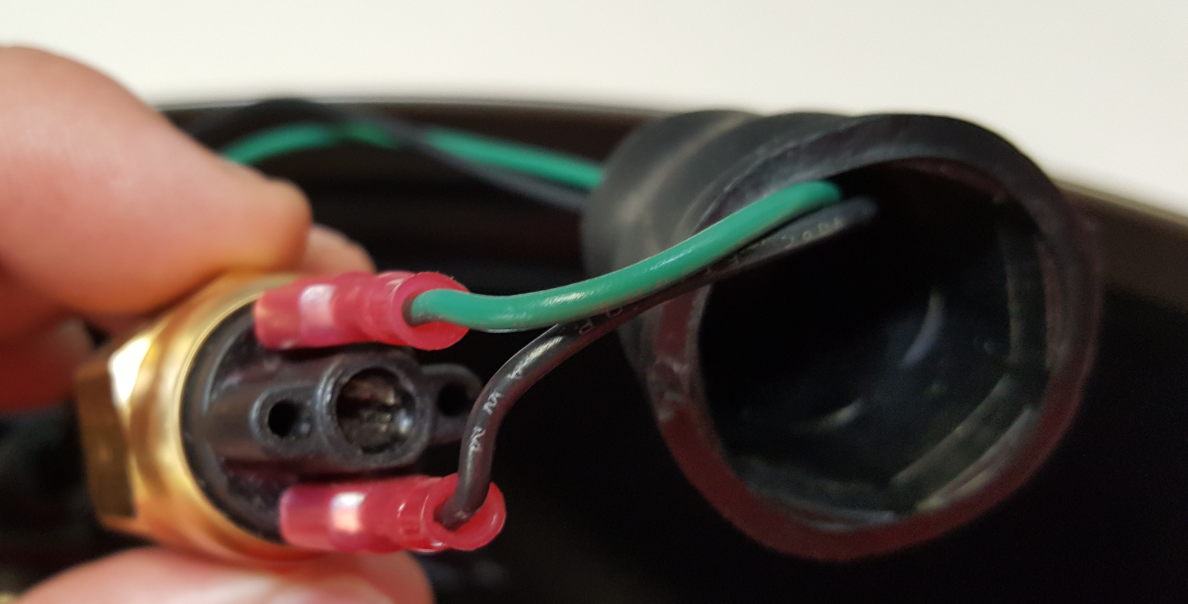

Disconnect the 3.5 mm jack or remove the two wire leads from the ATC board, which opens the circuit and allows the machine to run.

Recalibrate the Sensor

Reason: The air pressure sensor needs to be calibrated.

There is an adjustment screw under the rubber boot in the back of the machine for the pressure sensor. Set your regulator at the lowest pressure your air system provides and turn the screw until the “Air Pressure” LED on the status tab turns green. Inward should set it to a higher pressure and outward should set it to a lower pressure. (Newer sensors have a 3mm hex bolt, instead of the flat blade)

Replace the Sensor

Reason: There is a short in the circuit.

Find and repair the short.

An extreme solution that my be irreversible would be to cut the wires connecting the female 3.5 mm jack to the ATC control board and use wire nuts or electrical tape to cap them off. As long as the short was past where you cut, you will break the circuit and the ATC control board will see the “open” it needs to operate.

An extreme solution that my be irreversible would be to cut the wires connecting the female 3.5 mm jack to the ATC control board and use wire nuts or electrical tape to cap them off. As long as the short was past where you cut, you will break the circuit and the ATC control board will see the “open” it needs to operate.