Unpack and Mount the Machine

Basic Installation Procedure

Follow the steps below to complete basic mill installation.

Partial Stand Assembly

The pedestal of the stand should be assembled first. Refer to documentation that ships with the stand for information on assembly. Do not install chip pans or backsplash until after mill has been lifted onto the stand.

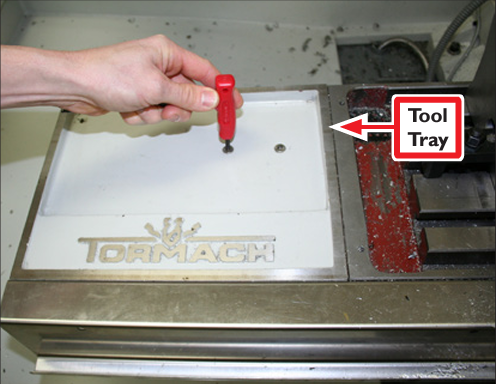

Remove Tool Tray

Carefully remove the Tool Tray from the pallet and set aside for installation later. (see Figure 3.7)

Remove Accessory Tool Box

A wooden Tool Box is nailed to the pallet. This box contains tools that are required for installation. Carefully remove box from pallet using pry bar.

NOTE: The Spindle Lockout Key – used to lock or unlock the spindle – is located in the Tool Box. The spindle with not rotate without the key inserted in the Operator Panel.

Assembling Y-Axis

The PCNC 1100 is supplied with the Y-axis Motor mechanically disconnected; install it before attempting to remove mill from pallet.

IMPORTANT! Damage to mill may occur if Y-axis Motor weight is supported by motor wires.

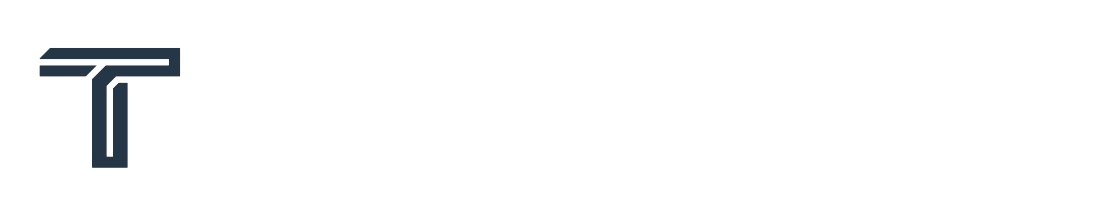

Unstrap Y-axis Motor from pallet. (see Figure 3.3)

Figure 3.3

Remove Y-axis Motor Mount Cover Plate from Y-axis Motor Mount. (see Figure 3.3)

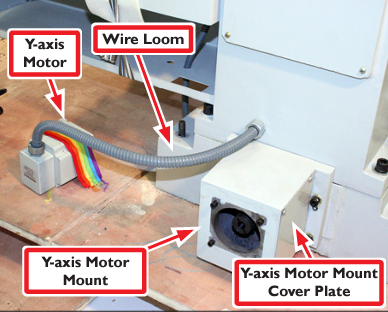

Using 4 mm hex wrench (included), loosen two Motor Shaft Coupling screws on end of Ball Screw. (see Figure 3.4)

Figure 3.4

Remove four cap head screws from Y-axis Motor Mount. (see Figure 3.3)

NOTE: Remove any paint around motor mount that could cause misalignment.

Use four cap head screws from step 4 to mount Y-axis Motor onto Y-axis Motor Mount. Wire loom should face toward floor. Make sure motor and motor mount faces are flush. (see Figure 3.3)

After tightening four cap head screws, back them off one-quarter turn so motor is free to self align.

Ensure coupling is centrally positioned between motor shaft and machined end of Ball Screw; tighten cap screws on coupling.

Tighten cap screws holding motor to motor mount securely.

Lift and Move Mill

WARNING! Transport and Lift Hazard: The transport, lifting, and moving of PCNC mill should be done by qualified professionals. Failure to do so may result in mill damage, serious injury or death.

WARNING! Transport and Lift Hazard: The transport, lifting, and moving of PCNC mill should be done by qualified professionals. Failure to do so may result in mill damage, serious injury or death.

Remove Mill from Pallet

The mill is secured to the shipping pallet with four bolts. Before attempting to lift mill, use wrench to remove nuts holding mill to pallet. This allows mill to be separated from shipping pallet when lifting.

Lifting Bar Kit

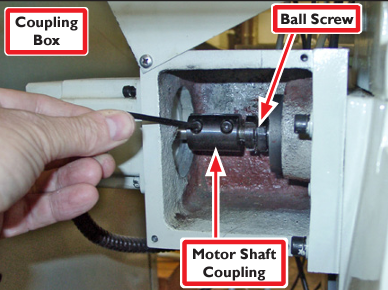

The preferred method for lifting the mill is from above, using the Lifting Bar Kit (PN 31446); as shown in Figure 3.5; use this method with either a forklift or engine hoist. The single Eye Bolt on the top of the column is suitable for lifting the entire weight of the mill. However, it is recommend that the Lifting Bar Kit be used. (see Figure 3.5 and Figure 3.6)

Refer to documentation that ships with Lifting Bar Kit for more information on use. Do not attempt to lift mill from above using any other method. If using an engine hoist, refer to the following table to determine the minimum distance necessary to straddle stand between hoist legs.

Machine | Measurement |

PCNC 1100 | 37” |

PCNC 770 | 29” |

Figure 3.5 Figure 3.6

Lifting from Below

It is also possible to lift the mill from below by inserting steel bars into two sets of opposing 7/8” diameter holes located in the machine base. The bars must be a minimum of 32” in length and should be made of solid steel. Do not use hollow pipe to lift mill.

WARNING! Crush Hazard: Keep hands and body parts clear when lowering mill onto stand. Failure to do so could result in serious injury or death.

WARNING! Crush Hazard: Keep hands and body parts clear when lowering mill onto stand. Failure to do so could result in serious injury or death.

Lowering Mill onto Stand

Position mill above stand and align one mill casting hole with one stand base hole; insert stud and thread into place. Repeat process for remaining three holes and loosely screw on four washers/nuts.

When mill is completely supported by stand, remove lifting tackle and tighten nuts to approximately 10 ft-lbs of torque.

Install Tool Tray (PCNC 1100 only)

Install the cast iron Tool Tray using provided screws to attach it to left side of machine table.

Install Drip Tray

Unstrap stainless steel Drip Tray from pallet; use provided screws to install.

Figure 3.7

Figure 3.8

Looking for more information?

This is a section of the PCNC 1100 operator's manual. To view the whole manual, go to Tormach document UM10349.

If you have additional questions, we can help. Create a support ticket with Tormach Technical Support at tormach.com/how-to-submit-a-support-ticket for guidance on how to proceed.