Validate Basic Installation

Validate the basic setup prior to installing any accessory kits.

IMPORTANT! Follow the Power Off/On Procedure detailed earlier. After powering on, jog the Z-axis up to remove shipping block between spindle nose and bed.

Verify Spindle Function

Use the Operator Panel controls to verify spindle function as follows (see Figure 3.14):

Turn Spindle Lockout key to I (unlocked position).

Select Manual for spindle mode.

Press Start; spindle begins to rotate.

Turn Spindle Speed Dial (RPM x 100) up and down to vary spindle speed.

Toggle between Forward and Reverse to switch spindle direction.

Press Stop; spindle stops.

Figure 3.14

Verify Limit Switch Function

Limit switches prevent the mill from exceeding its travel limits and provide a reference location during the mill homing procedure.

There are three limit switches, one for each axis of motion (X, Y, and Z), as shown in Figure 3.18.

Figure 3.18

If a limit switch is triggered, the mill is placed in a reset state.

To verify proper limit switch function:

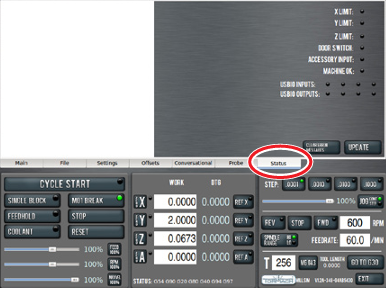

On the PathPilot interface, click the Status tab. (see Figure 3.19)

Figure 3.19

Manually depress X, Y, and Z limit switches by hand. (see Figure 3.18)

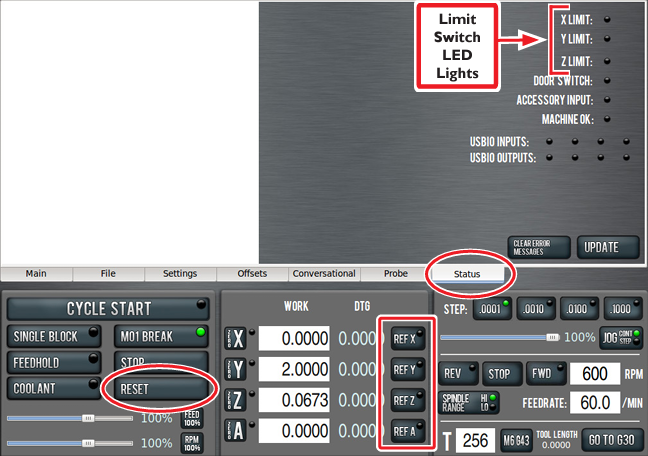

Verify that the corresponding limit switch LED light illuminates on the Status screen. (see Figure 3.20)

Figure 3.20

After verifying limit switch function, click the flashing Reset button. (see Figure 3.20)

Verify Axis Function

Reference the mill by clicking the Ref Z, Ref X, and Ref Y buttons; (see Figure 3.20) the mill moves.

Next, switch to the Main screen.

Use keyboard to verify axis motion:

To move X-axis, use the ←/→ keys.

To move Y-axis, use the ↑/↓ keys.

To move Z-axis, use the Page Up/Page Down keys.

To test the optional jog shuttle:

Press the corresponding axis button (X, Y, or Z) to select the axis.

Twist shuttle ring of jog shuttle to move axis. Twist in opposite direction to reverse direction.

Coolant On/Off

The coolant pump can be controlled manually using the Coolant switch on the operator panel. This switch has three positions: On, Off, and Auto. The Auto position allows PathPilot to control the coolant pump. To operate:

Press On to turn the coolant pump on.

Press Off to turn the coolant pump off.

Press Auto to switch to operating system control of coolant.

In Auto mode, click the Coolant button on the PathPilot interface to turn coolant on. Click the button again to turn coolant off.

Looking for more information?

This is a section of the PCNC 1100 operator's manual. To view the whole manual, go to Tormach document UM10349.

If you have additional questions, we can help. Create a support ticket with Tormach Technical Support at tormach.com/how-to-submit-a-support-ticket for guidance on how to proceed.