Legacy ATC Alignment and Troubleshooting - PCNC 440

Background

Depending on when you purchased your PCNC 440, you may have one of two different styles of ATC’s. This page will go over the alignment and troubleshooting of the legacy unit.

Alignment

Reason: Upon install, or after a ATC malfunction, adjustment may be needed on your ATC.

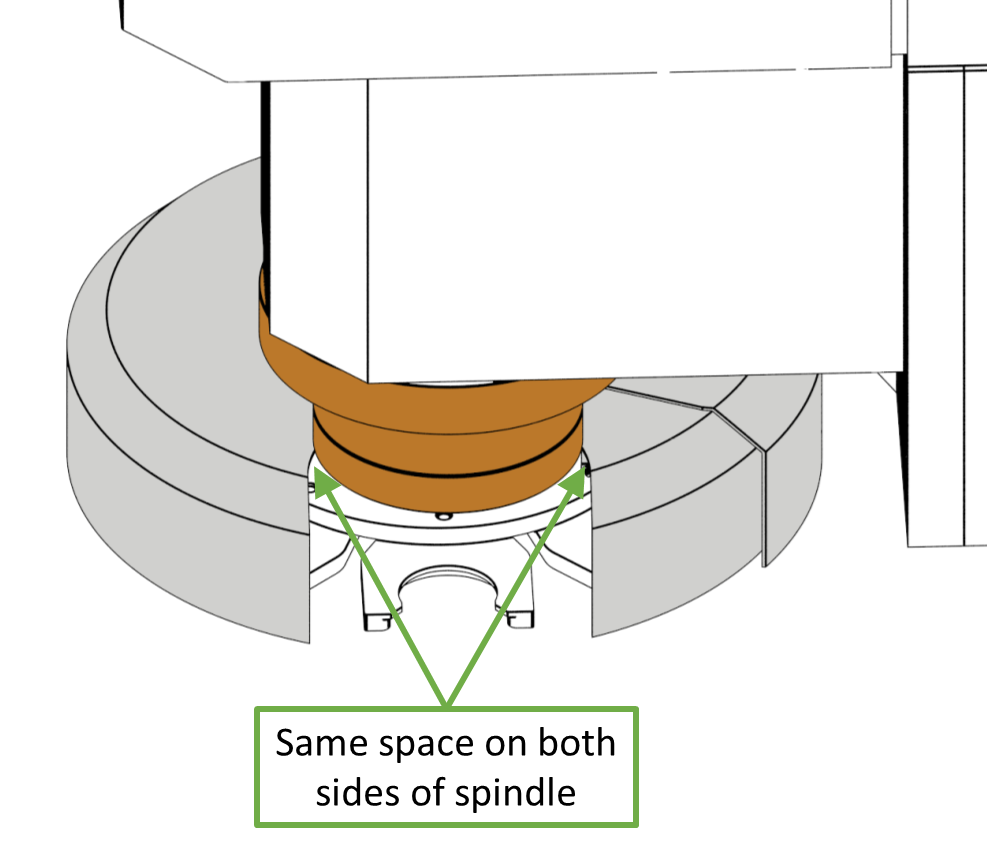

Align the ATC with the Spindle Nose.

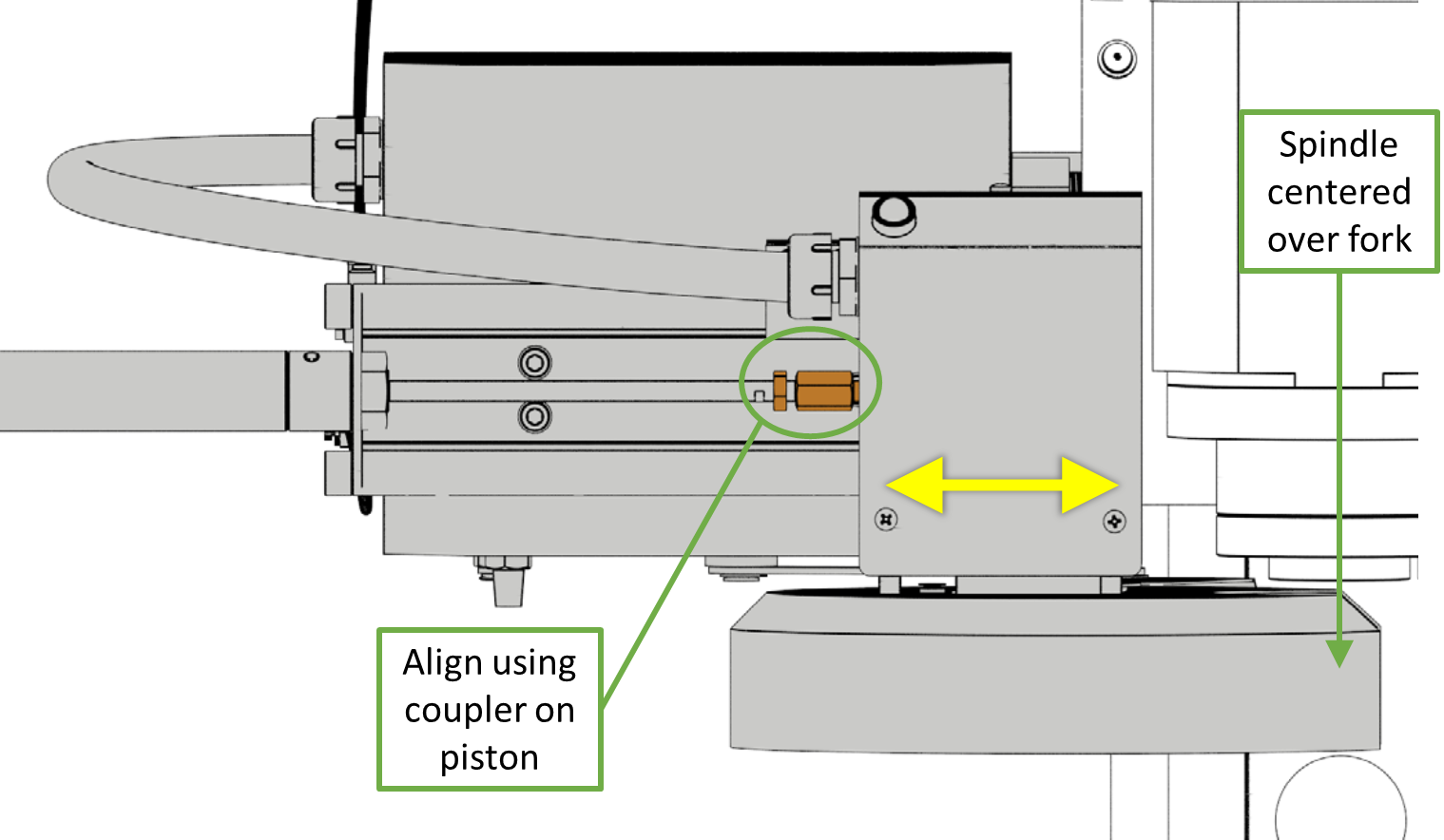

Align the ATC in the X direction.

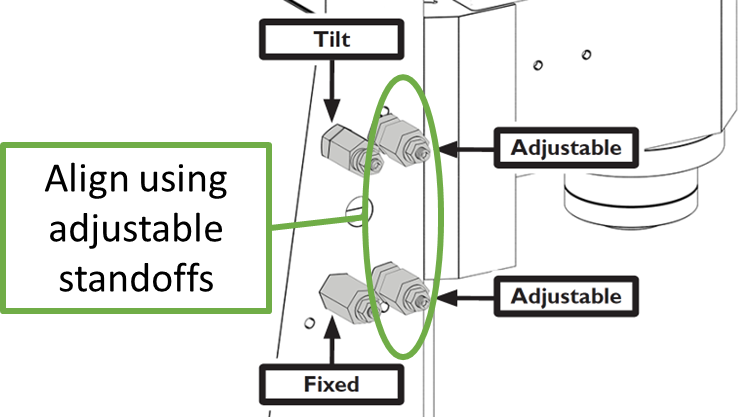

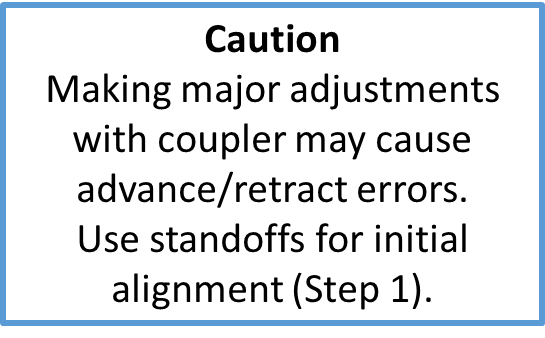

Adjust ATC Tilt in X Axis

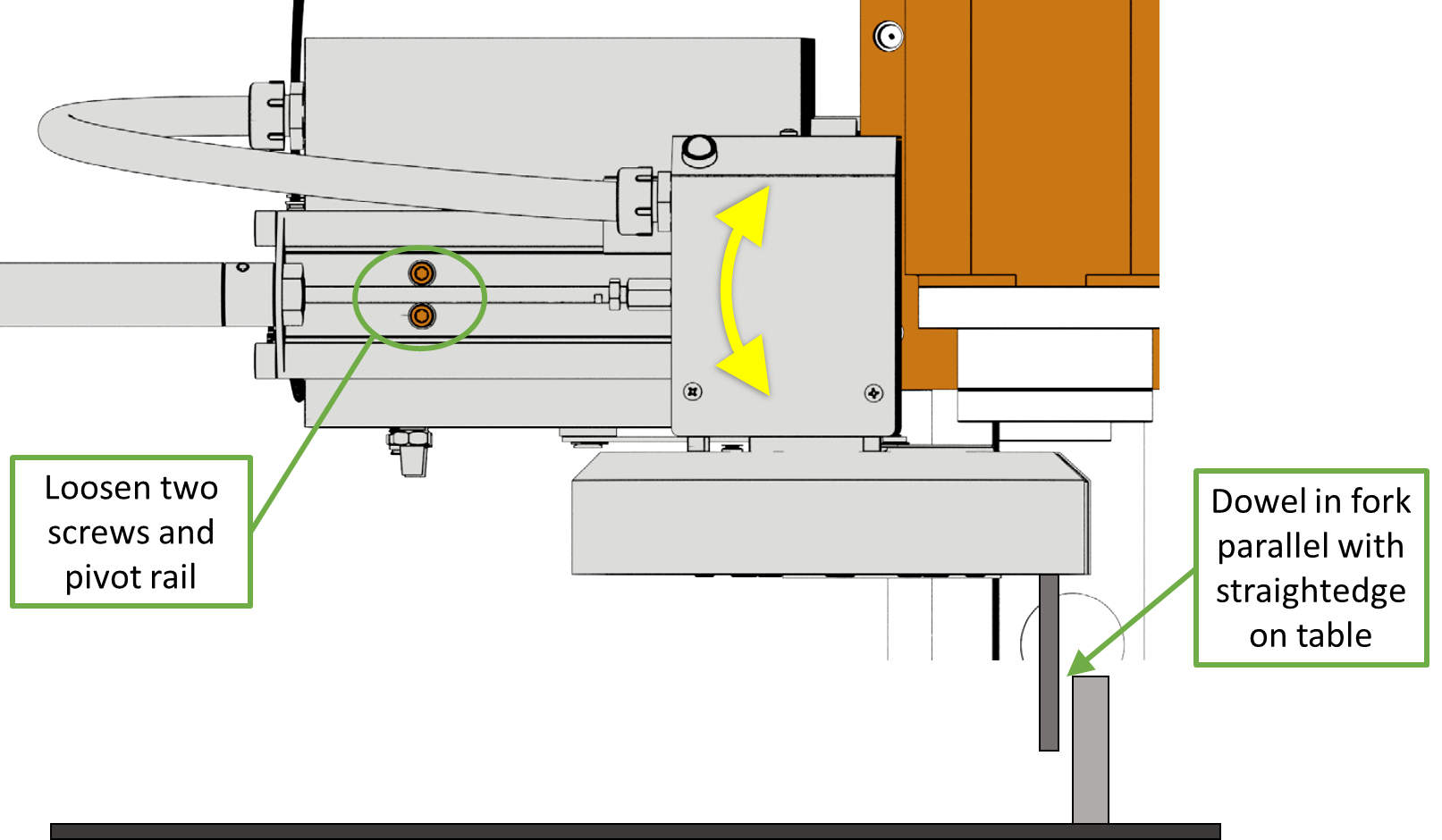

Adjust ATC Tilt in Y Axis

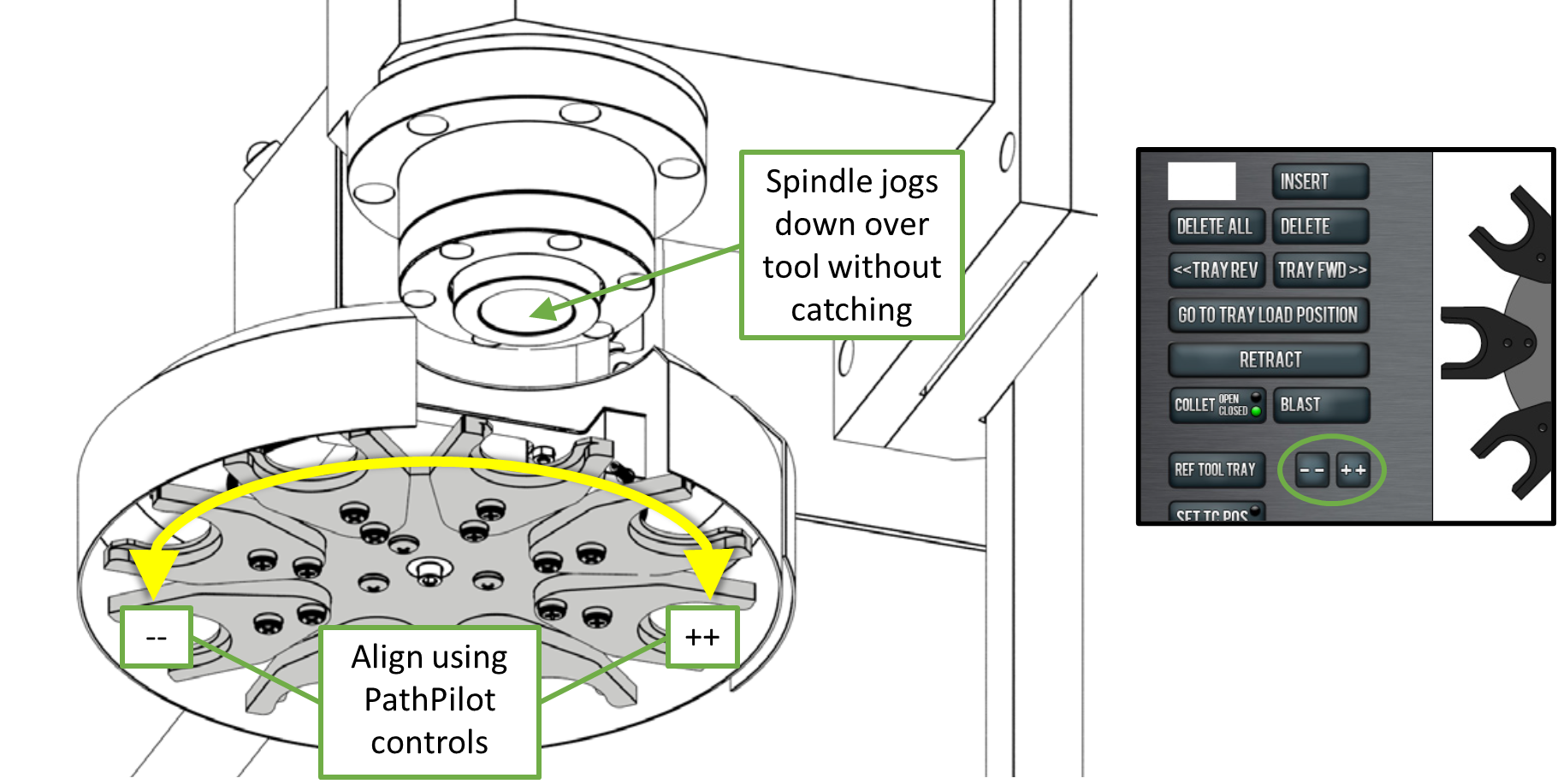

Adjust Tray Rotation

Troubleshooting

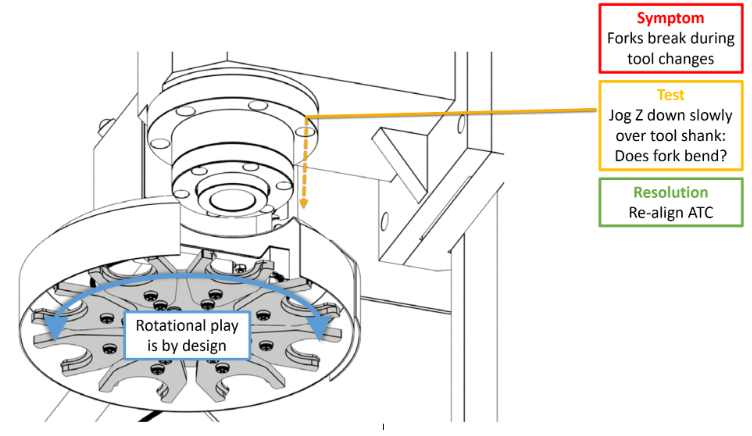

Forks Breaking During Tool Changes

Reason: Misalignment

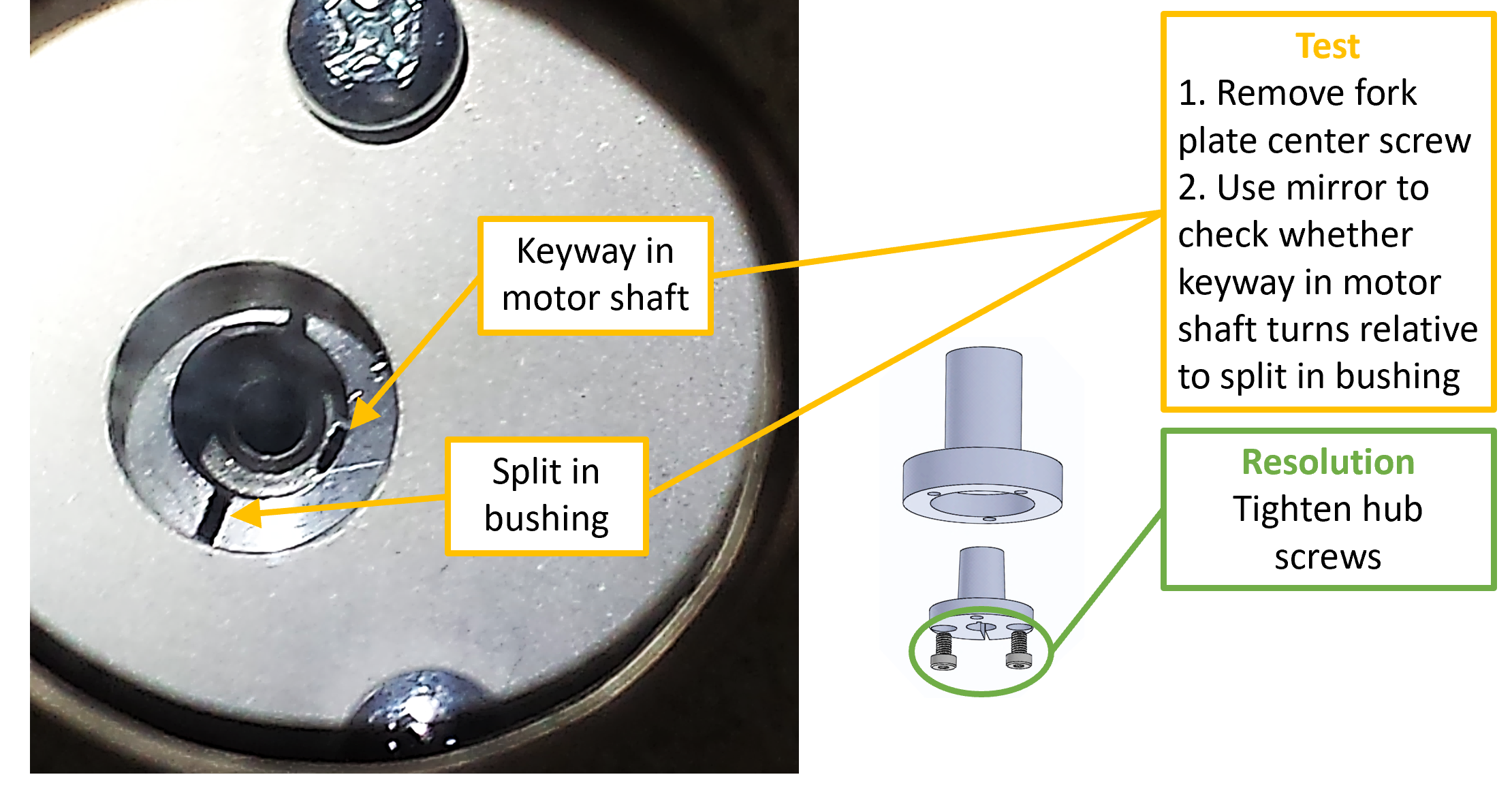

Forks Breaking After Several Successful Tool Changes

Reason: Loose hub

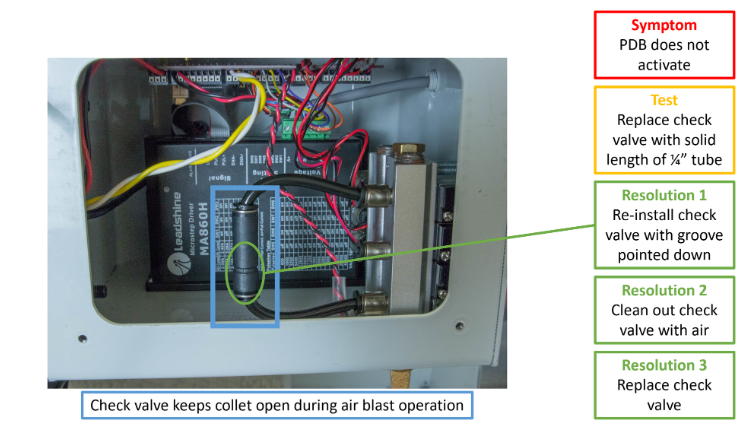

Power Draw Bar Does Not Activate

Reason: Check valve

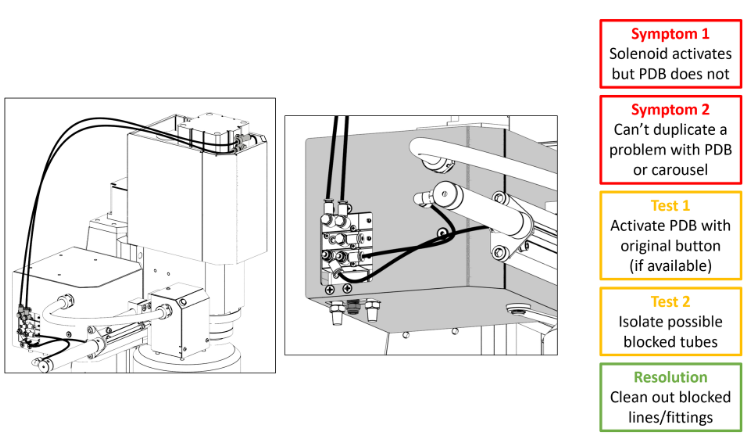

Solenoid Activates but PDB Does Not

Reason: Blocked air lines

Low Air Pressure

Reason: Compressor not keeping up. Optional Legacy ATC air pressure sensor not adjusted properly

Check to make sure your PSI is set to at least 90 PSI. Make sure your FRL reflects the same value.

If you have the air pressure sensor installed - see Low Air Pressure or Malfunctioning Air Pressure Switch - PCNC 440 for adjustment.

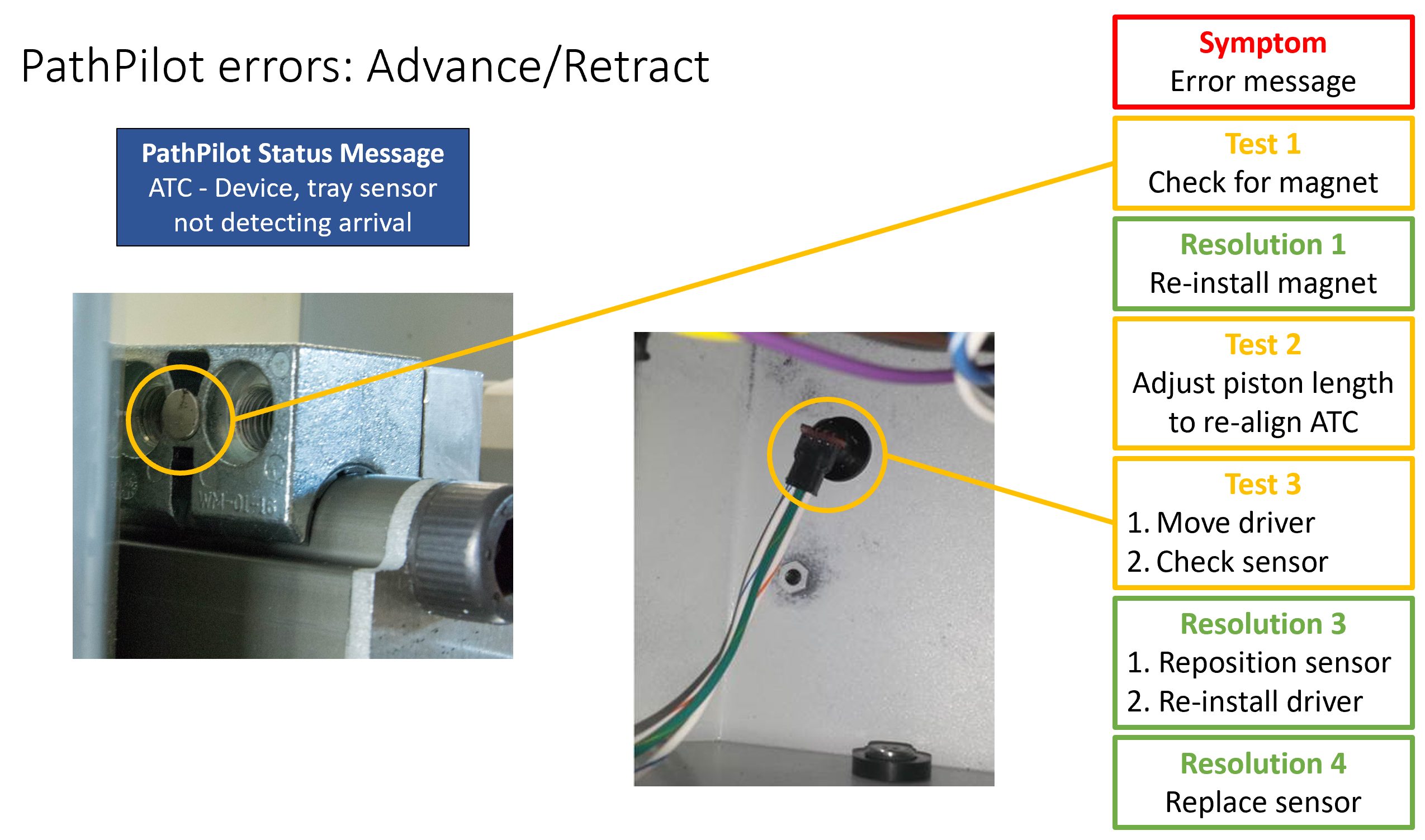

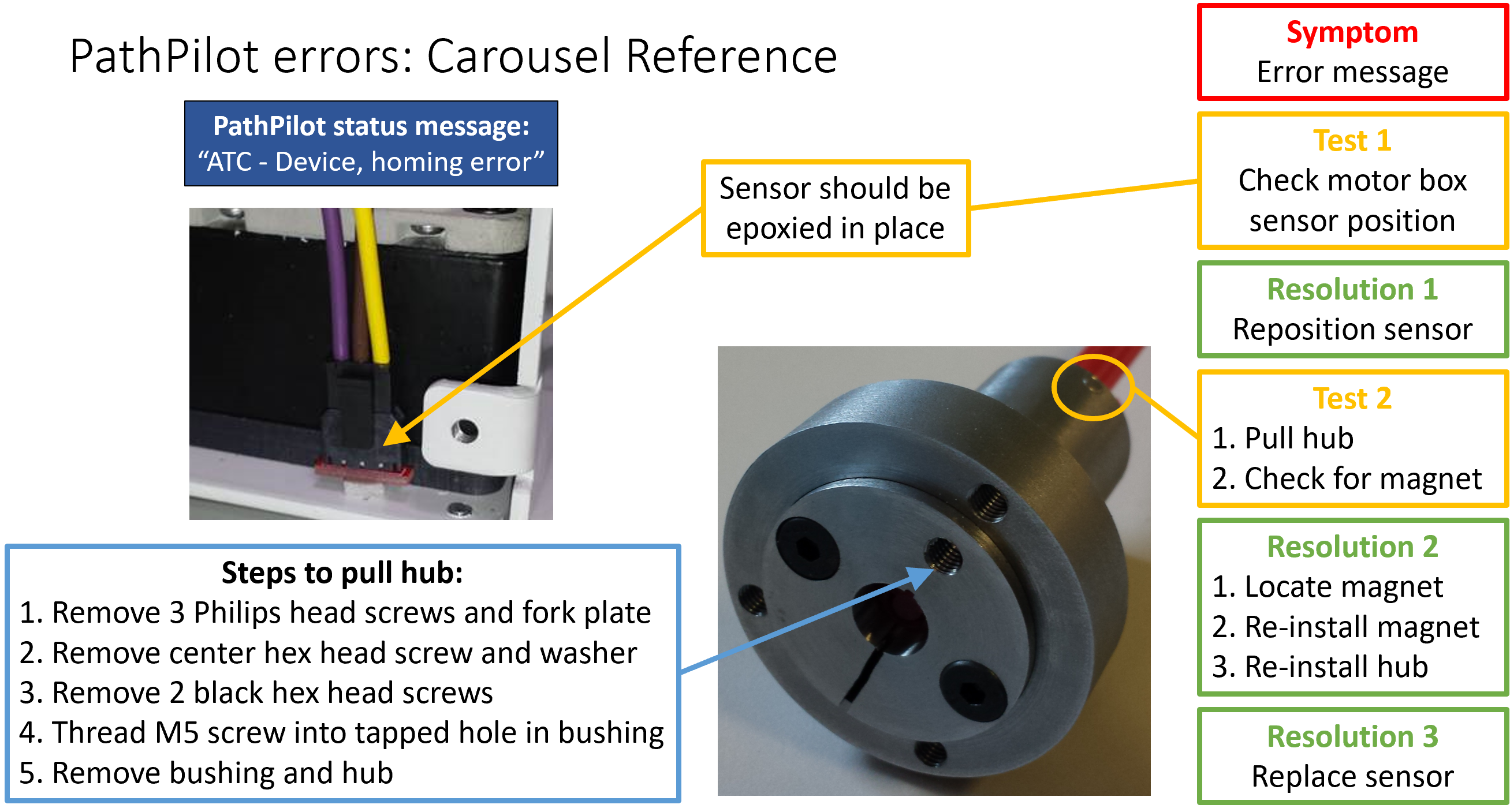

ATC Fails to Reference Tray

Reason: Misaligned sensor or magnet. Bad sensor.

ATC Tray Sensor Not Detecting Arrival

Reason: Misaligned magnet/sensor. Bad sensor.