For machinists and small shops looking to increase efficiency and automate part production, integrating a bar puller into your CNC lathe setup can be a game-changer. A bar puller is a lathe accessory that, when used with an automatic collet closer, pulls stock forward between cycles to automatically position fresh material for each part — enabling hands-free operation for batch machining. In this guide, we’ll walk through how to set up and use a bar puller with the 15L Slant-PRO CNC lathe. Whether you’re producing 50 or 500 parts, a bar puller streamlines bar advancement and boosts productivity with minimal operator intervention.

Mounting Options for the Bar Puller on the 15L Slant-PRO

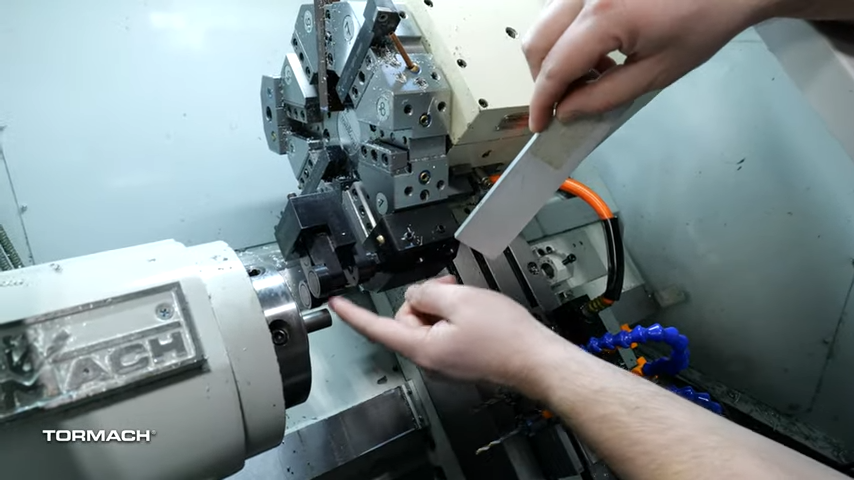

Tormach offers two versions of the bar puller for the 15L Slant-PRO lathe:

-

A traditional 3/4-inch stick mount, which can be used on the lower X-slide if you have a quick-change tool post.

-

A 3/4-inch round shank version, designed to fit into a boring bar holder.

Functionally, both versions are identical. The choice between them depends on your lathe configuration and how you prefer to mount tools. Keep in mind that the standard 3/4-inch version can obscure turret mounting screws, making adjustments more difficult.

How to Set Tool Offsets for the Bar Puller

Like any cutting tool, the bar puller requires correct tool offsets to function properly.

Z-Axis Offset:

This can be set visually. Simply align the front rollers of the bar puller with the end of your part and set Z0 at that point. Precision isn’t critical here.

X-Axis Offset:

Setting the X offset is more nuanced because the bar puller grips the material with spring-loaded rollers. To determine the center of the rollers:

-

Use a shim or piece of flat material that spans both rollers.

-

Slowly jog the tool in until the shim can no longer move freely — this is your contact point.

-

Measure the roller radius (0.531 in), add the shim thickness (e.g., 0.25 in), and the bar radius (e.g., 0.3125 in for 5/8” stock). Multiply the result by two to get the total X-axis offset.

-

Enter that final diameter into your tool offset table.

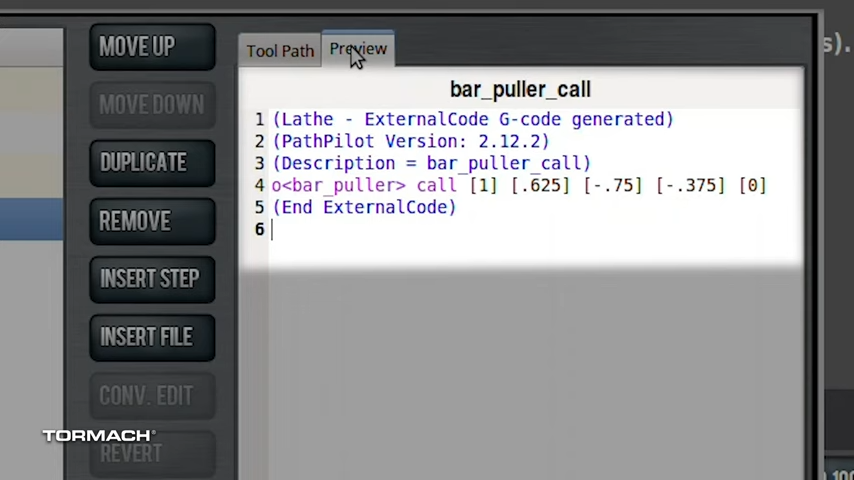

Programming the Bar Puller with PathPilot

Tormach provides a macro that automates the bar puller operation. The macro takes the following arguments:

-

Tool number: Which tool in the turret or quick-change post is your bar puller?

-

Material diameter: In inches.

-

Z position to grip: Where the bar puller contacts the material.

-

Pull distance: How much the bar is pulled forward from its previous position.

-

Mounting type: 0 for turret mount, 1 for quick-change post.

You can insert this call into your part program as a separate subroutine. In PathPilot®, use the “Insert File” function to add it easily.

Automating Production with Looping Logic

To run the same program multiple times automatically:

-

Add a M98 P100 L20 line at the beginning. This tells the program to call subroutine P100 twenty times.

-

Define subroutine P100 above the main code.

-

Replace the program’s M30 with M99 to enable the loop.

This approach allows you to run large batches with no need for manual intervention between parts. When the stock runs out, you’ll be left with only a small remnant bar — ready to reload and restart the process.

Download and Use the Bar Puller Macro

Tormach plans to include the bar puller macro in an upcoming PathPilot software update. Until then, the file will be available for download on the Tormach Forums. Once downloaded, place the file in your /subroutine folder on your PathPilot system. From there, you can call it in your G-code or conversational program using the method described above.

Boost Lathe Productivity with Automated Part Cycles

The bar puller is an invaluable addition for users of the Tormach 15L Slant-PRO CNC lathe who want to automate part production. By setting up the bar puller correctly and incorporating the provided macro into your G-code, you can run long batches with minimal supervision. It’s a smart solution that enhances efficiency, repeatability, and workflow—perfect for small machine shops, R&D teams, and anyone looking to make the most of their CNC lathe.