All Axes Won't Move When Commanded - PCNC 1100

Background

Your machine axes require power and control signals to work. If either of those are disrupted you can lose any or all of your axes motion. If only one motor is not working go to, One Axis Won't Move (or Only Moves in One Direction), and Other Axes Move - PCNC 1100.

Tools

Digital Multimeter

Metric Allen Keys

Small Flat Blade Screw Driver

Reseat the Connectors on the Machine Control Board

Reason: Control signals aren’t reaching the electronic driver modules.

Inspect the stepper driver controller lights.

Some controller lights are on: One Axis Won't Move (or Only Moves in One Direction), and Other Axes Move - PCNC 1100.

All the controller lights are off: Continue to the next step.

Power off the machine.

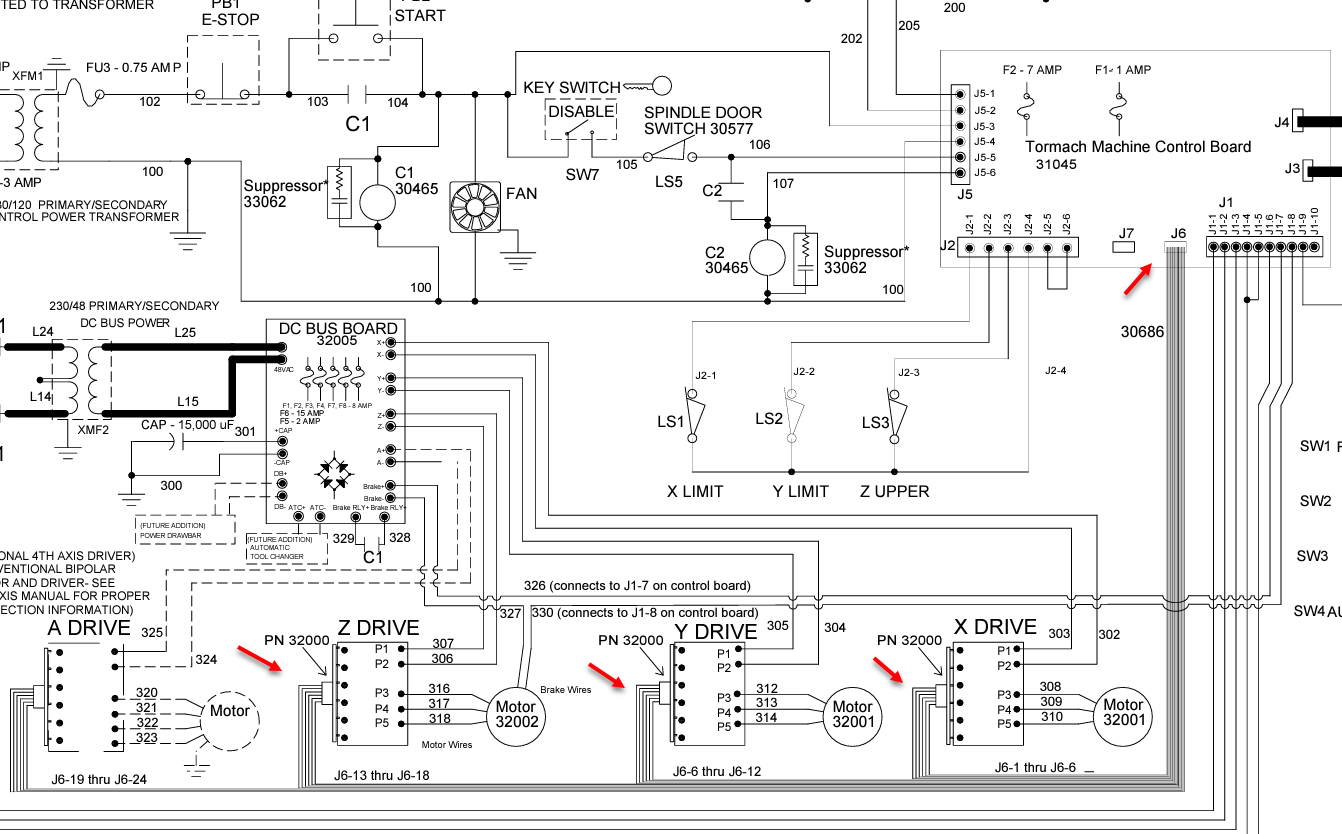

Examine the data cable at the machine control board and the axes drivers.

Machine control board: J6 (26 pin IDC ribbon cable)

Stepper driver controllers: 10 pin IDC (ribbon cable)

J6-1 - J6-6 (X-axis)

J6-7 - J6-12(Y-axis)

J6-13 - J6-18 (Z-axis)

PCNC 1100 J6 Ribbon Cable

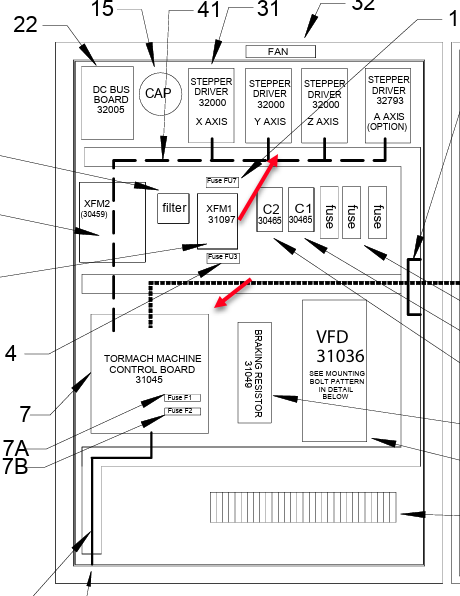

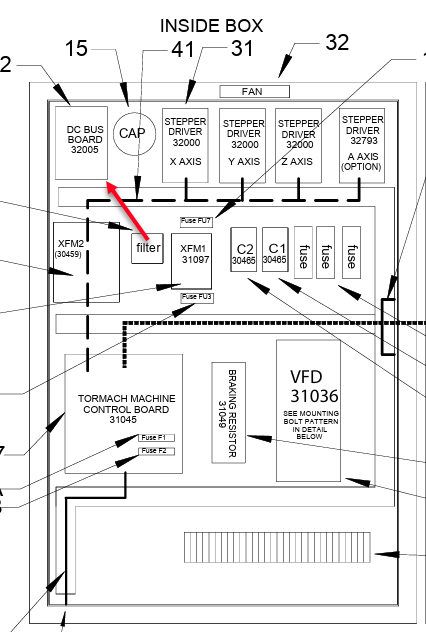

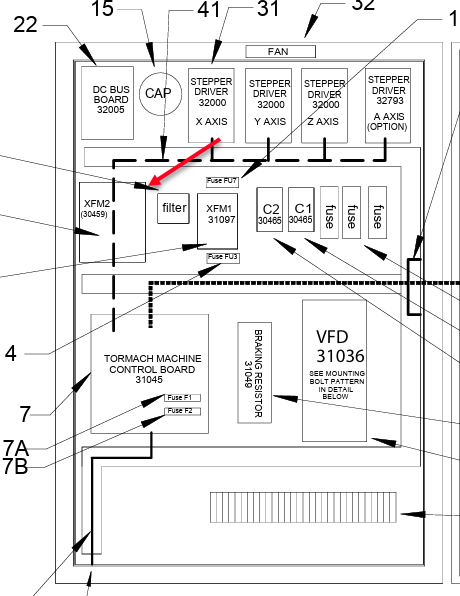

PCNC 1100 Main Control Board and Driver Locations

Examine the power and control cables at the DC-BUS and the stepper driver controllers removing, inspecting, and re-connecting them to ensure they are seated.

DC-Bus/Stepper driver controllers: Spade connectors/Degson style

302/303 (X-axis)

304/305 (Y-axis)

306/307 (Z-axis)

PCNC 1100 Stepper Driver Power Wires

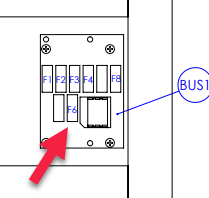

PCNC 1100 DC-BUS Location

If there is any discoloration, replace the cable and driver.

Continue to the next troubleshooting topic.

Inspect the DC-BUS board

Reason: The DC-BUS is malfunctioning.

Inspect the DC-BUS for power by determining if the green power light is illuminated.

If it does: The motors or stepper driver controllers will be illuminated, if the DC Bus Axis Fuses are not blown. To learn how to check individual fuses, see: One Axis Won't Move (or Only Moves in One Direction), and Other Axes Move - PCNC 1100 | Inspect-the-DC-Power-Supply

If it doesn’t: Continue to the next step.

Power off the machine.

Measure the resistance across the F6 fuse with digital multimeter set to resistance.

Replace the fuse if the digital multimeter reads OL, shows a resistance in the MΩ, and/or doesn’t produce continuity tone.

If the fuse measures 0-5 Ω, reinstall it into the DC-BUS.

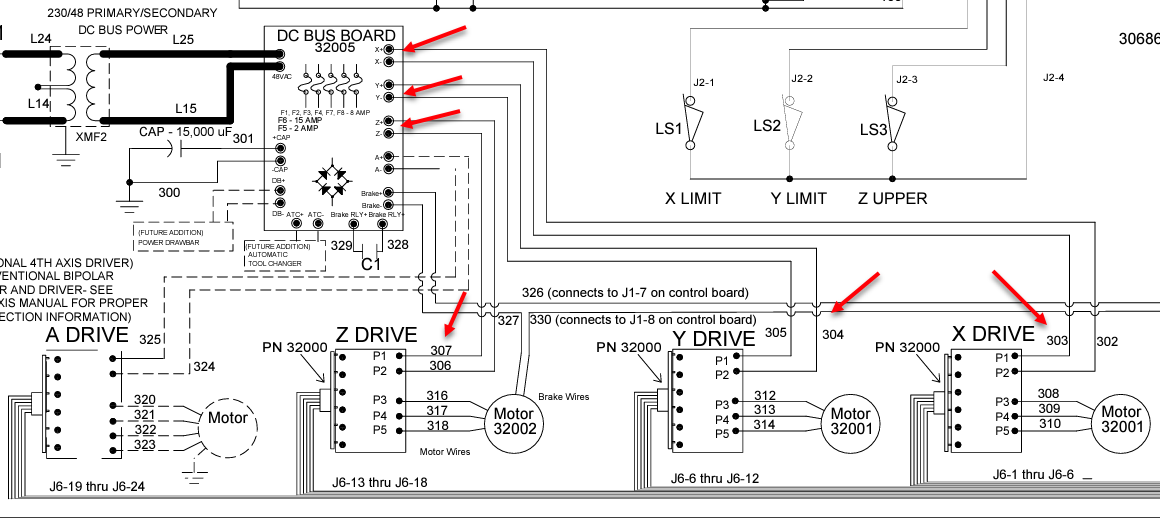

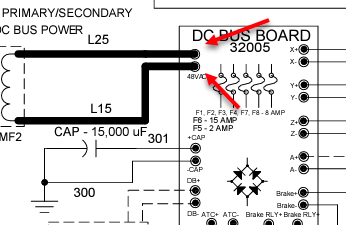

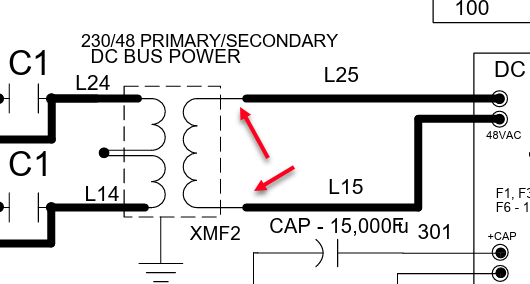

Power on the machine and measure the Vac entering the DC-BUS on:

L25

L15

PCNC 1100 DC-BUS

Continue to the next troubleshooting topic.

Inspect the XMF2 Transformer

Reason: The transformer is shorted

Power off the machine.

Remove L25 and L15 from the transformer.

PCNC 1100 XFM2 Location

Power the machine back on.

Take an AC reading between the terminals L25 and L15 were on.

If you do not see 48 Vac, continue to the next troubleshooting step.

Check the C1 Contactor

Reason: The C1 is defective.

Power on the machine and take it out of reset.

Inspect the C1 to see if the center bar has been pulled in.

If bar is in: The C1 is latched. Using a digital multimeter set to Vac, measure for 220 Vac between:

L14

L24

Press and hold the Reset button on the operator box and observe the C1. Then release the Reset button and observe the C1.

If the bar only stays in when the button is pressed: There is a loose coil wire, short, or the C1 has malfunctioned.

If the bar never gets pulled in: See Machine Won't Power On - PCNC 1100