PCNC 440 X-Axis Ball Screw Replacement

Background

In the event the Y-Axis Ball Screw needs to be replaced, the procedure below with guide you through the process of removing the ball screw.

Tools

Metric hex wrench set

Remove the Ball Screw

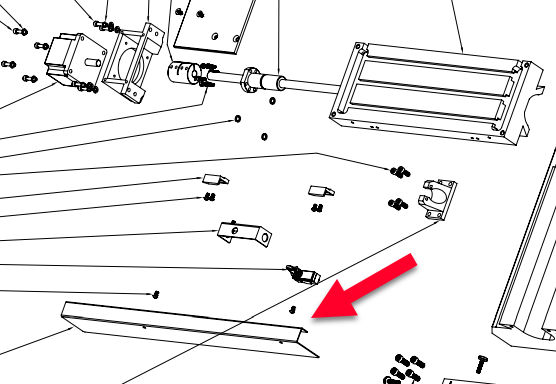

Remove the stainless steel X-axis limit switch guard.

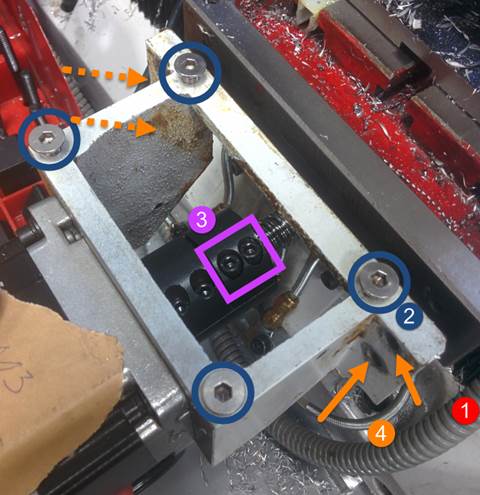

Remove the X-axis motor cover by removing the 4 flat-head cap screws.

Detach the ball screw side of the motor coupling by loosening the two socket head cap screws.

Remove the X-axis motor mount assembly by removing the four socket head cap screws securing the mount casting to the table.

Carefully slide the table to the right to expose the ball nut mount.

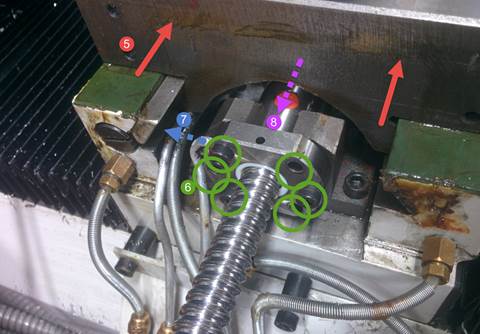

Detach the ball nut from the ball nut carrier casting by removing the six socket head cap screws.

Carefully remove the x-axis ball nut oil distribution line from the ball nut.

Remove the x-axis ball screw assembly from the machine.

Install Replacement Ball Screw

To reassemble, reverse steps 1-8 making sure to reconnect the X-axis Ball Nut oil line. When reassembling, leave the X-axis motor mount assembly cap screws finger tight. Reconnect the coupler but hold short of putting all the covers back on. Power up your machine and controller and carefully jog the X-axis all the way to the right. Once you have jogged to the table to the right you can snug down the mount’s cap screws and reattach the cover plate and limit switch cover. Then, reference the Lost Motion and ACB/Gib adjustment document.