Background

Your machine axes require power and control signals to work. If either of those are disrupted you can lose any or all axis motion. If all of your motors are not working, go to All Axes Won't Move When Commanded - 770MX .

Tools

-

Digital multimeter

-

Small flat-bladed screwdriver

-

Metric hex wench set

-

Phillips screwdriver

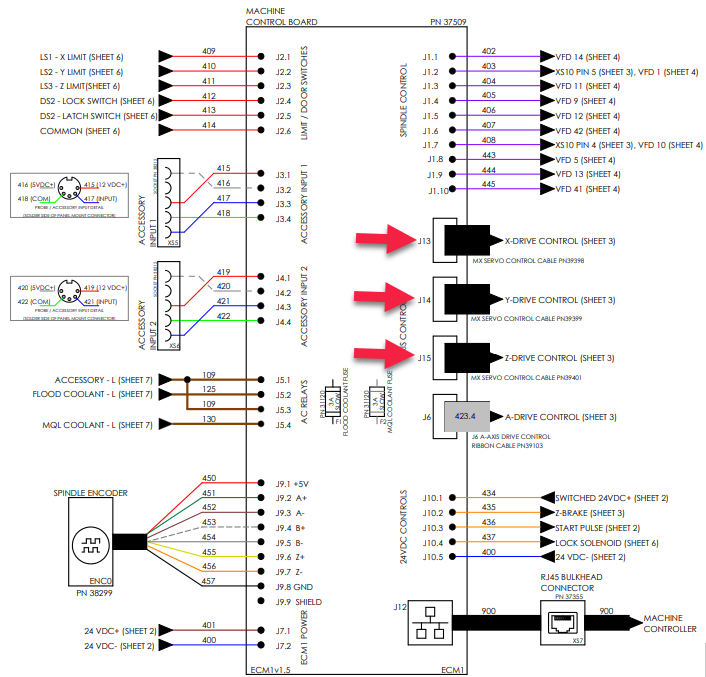

Reseat the Connectors on the ECM Board and Motors

Reason: Control signals aren't reaching the electronic driver modules/servo motors.

-

Power off the machine.

-

Examine the data cables at the machine control board and the servos removing then re-connecting them to ensure they are seated.

-

Machine control board: Degson style

-

424 (J13) (X-axis)

-

425 (J14) (Y-axis)

-

426 (J15) (Z-axis)

-

-

Servos: Molex style

-

-

Examine the power cables at the DC-BUS and the servos removing then re-connecting them to ensure they are seated.

-

DC-Bus: Spade connector

-

210/211 (X-axis)

-

220/221 (Y-axis)

-

230/231 (Z-axis)

-

-

Servos: Molex style

-

-

Continue to the next troubleshooting topic.

Inspect the Servo

Reason: There's a defective or malfunctioning servo/cable.

-

Examine the motor status LED and compare it to the manufacturer's blink code document. ClearPath Blink Codes.pdf

-

Continue to the next troubleshooting topic.

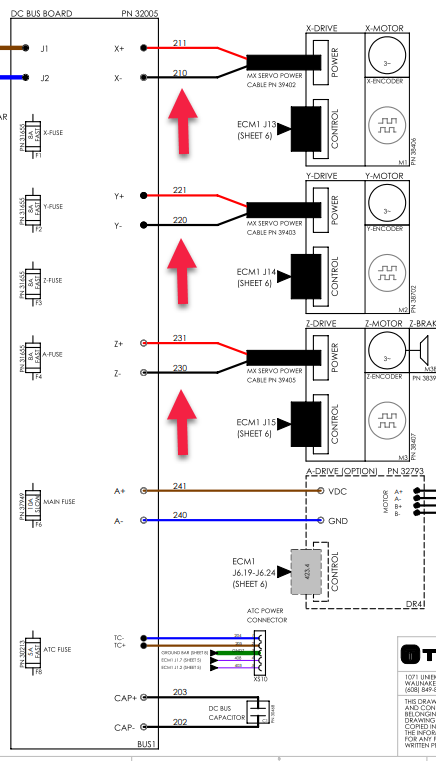

Inspect the DC Power Supply

Reason: There's a blown fuse on the DC-BUS board.

-

Power on the machine and take it out of reset.

-

Examine the green LED on the DC-BUS board.

-

If the green LED is not illuminated: Go to All Axes Won't Move When Commanded - 770MX

-

If the green LED is illuminated: Continue to the next step.

-

-

Power off the machine.

-

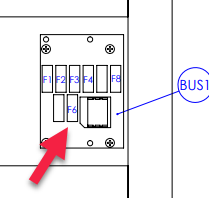

Remove the cover from the DC-BUS board.

-

Using the table below, locate the corresponding axis fuse and measure its resistance across the fuse with a digital multimeter set to resistance.

-

Replace the fuse if the digital multimeter reads OL, shows a resistance in the MΩ, and/or doesn’t produce continuity tone.

770MX DC Bus Board -

If the fuse measures 0-5 Ω, reinstall it.

-

|

Function |

Fuse Number |

Amperes |

Speed |

|---|---|---|---|

|

X-Axis |

F1 |

8 A |

Fast |

|

Y-Axis |

F2 |

8 A |

Fast |

|

Z-Axis |

F3 |

8 A |

Fast |

|

A-Axis |

F4 |

8 A |

Fast |

|

Main DC-BUS fuse |

F6 |

10 A |

Slow |

|

ATC |

F8 |

5 A |

Fast |

A blown fuse can be the result of a defective driver or wiring. Inspect the axis' wiring carefully and repair any damage observed. If you replace a fuse and it immediately blows, it's likely a defective axis drive or its wiring.

Inspect the Motor Cables

Reason: There's a defective motor or motor connection.

-

Power off the machine.

-

Unplug the servo's cables and examine the motor and cables for signs of coolant or contamination.

-

If there is coolant or contamination: Replace the servo and cable.

-

If there is nothing: Reconnect the cable and continue to the next step.

-

-

Power on the machine.

Inspect the Motor Coupling

Reason: There's a loose axis motor coupling.

-

Jog the axis and listen to determine if you can hear the motor run.

-

Remove the cover plate over the coupling and make witness marks across the coupling and ball screw.

-

Jog the axis to determine if the motor's turning but the screw isn't.

-

If the coupling is slipping, locate the hex screws and tighten them down.

-

Ensure Oil is Getting to the Motion System

Reason: Oil isn't getting to the ways and ball screw.

-

Examine the oil level in the oiler.

-

Investigate the oiling system for lack of oil and/or plugged lines (for more information, see Tormach service bulletin SB0031).

Push Fresh Oil Through the System

Reason: There's oil residue from long-term storage.

-

Repeatedly pump oil and slowly jog the axis.

-

If the machine has been sitting for a significant amount of time, the oil layer may have a suction effect. Continue to the next section to see how to manually move an axis on your mill.

-

Axis is Stuck at a Max Travel Limit

Reason: The axis motor faulted on start-up at end of travel.

Never manually release the Z-axis on a machine. If you do, the head will fall.

-

Power off the machine.

-

Locate the motor couple of the axis that is producing the error and turn it by hand away from the end of travel.

-

Power on the machine and take it out of reset.

-

Try to reference the axis that was faulting.

Inspect the Gibs Position

Reason: The gibs are too tight.

-

Follow the appropriate gib adjustment procedure below for your machine:

-

Follow Gib adjustment procedure: Mill Gib/AC Bearing Adjustment and Backlash Compensation - 770MX

-

Clean the Ball Screw

Reason: There's debris on the ball screw.

-

Clean the ball screw.

Debris on the ball screws can rapidly accelerate wear and reduce the lifespan of your machine. Evaluate if additional measures are required to protect your machine's ball screws and ways (like supplemental dust collection).