One Axis Won't Move (or Only Moves in One Direction), and Other Axes Move

Background

Your machine axes require power and control signals to work. If either of those are disrupted you can lose any or all axis motion. If all of your motors are not working, go to All Axes Won't Move When Commanded - PCNC 440.

Tools

Digital multimeter

Small flat-bladed screwdriver

Metric hex wench set

Phillips screwdriver

Reseat and Inspect the Connectors on the MX3660 and Motors

Reason: Control signals aren't reaching the electronic driver module

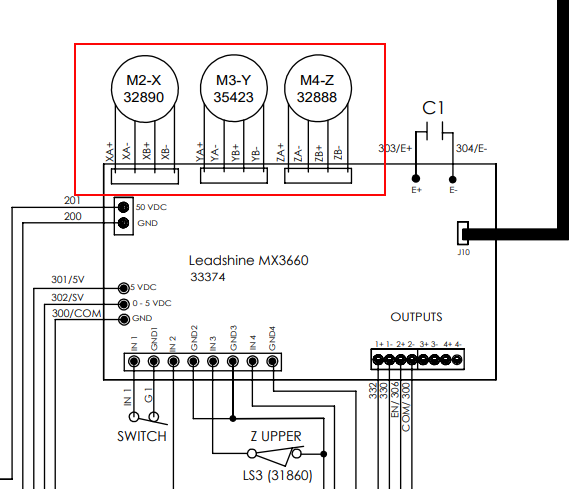

Stepper Connections on MX3660

Inspect the Motor’s Drivers

Assess the State of the Motor or Stepper Driver Controller

Reason: There's a defective or malfunctioning axis driver/cable.

Power on the machine and take it out of reset.

Examine the LEDs of the motor drivers on the MX3660 driver.

If the stepper driver controller has an illuminated green light: It is ready and operating normally and you should continue to the next topic.

If the stepper driver controller has an illuminated red LED: The machine should be power cycled to try and reset the stepper driver controller or the stepper driver controller needs to be replaced.

If the are no lights on the stepper driver controller: Continue to Inspect you power source.

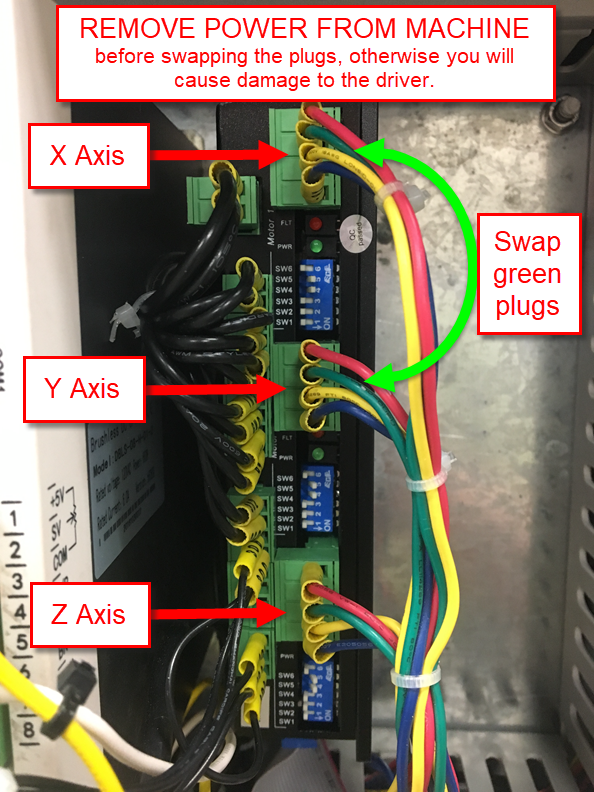

PCNC 440 Driver Swap

Power off the machine.

Verify that the wires and cables are in their original position.

Swap the green plugs between two different axes.

MX3660

Power on the machine.

The controls on the machine change, depending on the ribbon cables you swapped.

The controls on the machine change, depending on the ribbon cables you swapped.Jog the malfunctioning axis and swapped axis in both directions.

If the malfunctioning motor now functions properly: It is likely that the malfunctioning axis driver is defective. A replacement MX3660 Driver will be needed

If the malfunctioning motor continues to move erratically: Continue to the next troubleshooting topic; but, it is likely that the malfunctioning axis motor is defective.

Inspect the DC Power Supply

Reason: There's a blown fuse on the DC-BUS board.

Inspect the DC power supply for power by examining if the green power light is illuminated.

If it does: The stepper driver controllers or motors will be illuminated.

If it doesn’t: Go to All Axes Won't Move When Commanded - PCNC 440

Inspect the Motor Coupling

Reason: There's a loose axis motor coupling.

Jog the axis and listen to determine if you can hear the motor run.

Remove the cover plate over the coupling and make witness marks across the coupling and ball screw.

Jog the axis to determine if the motor's turning but the screw isn't.

If the coupling is slipping, locate the hex screws and tighten them down.

Ensure Oil is Getting to the Motion System

Reason: Oil isn't getting to the ways and ball screw.

Examine the oil level in the oiler.

Investigate the oiling system for lack of oil and/or plugged lines (for more information, see Tormach service bulletin SB0031).

Push fresh Oil Through the System

Reason: There's oil residue from long-term storage.

Repeatedly pump oil and slowly jog the axis.

If the machine has been sitting for a significant amount of time, the oil layer may have a suction effect.

Inspect the Gibs Position

Reason: The gibs are too tight.

Follow the appropriate gib adjustment procedure below for your machine:

Clean the Ball Screw

Reason: There's debris on the ball screw.

Clean the ball screw.

Debris on the ball screws can rapidly accelerate wear and reduce the lifespan of your machine. Evaluate if additional measures are required to protect your machine's ball screws and ways (like supplemental dust collection).