If you have an automatic oiler, view those instructions here.

Installation

-

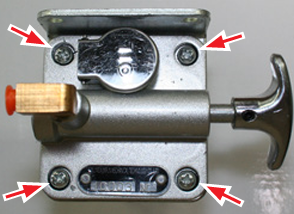

Remove four bracket screws shown in Figure 1.

-

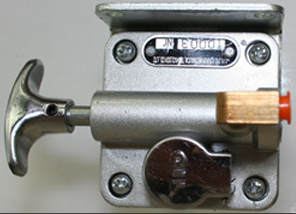

Reverse plunger as shown in Figure 2 and reinstall screws.

-

Using two M6 x 15 mm socket head cap screws, mount oiler to pre-drilled holes on side of lathe (see Figure 3).

-

Identify the access panel on the right side of the machine’s enclosure. Remove the 16 screws securing the panel to the enclosure, and set the screws and the panel aside.

-

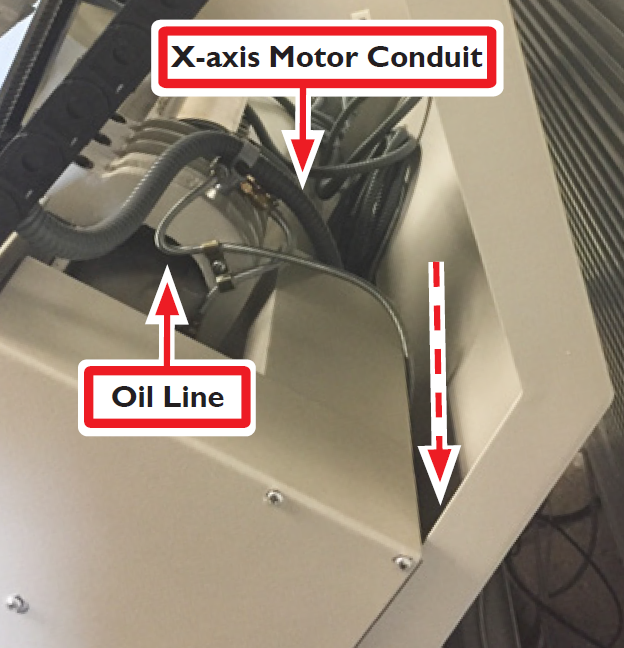

Find the oil line inside the machine’s enclosure.

-

Route the oil line to the manual oiler:

-

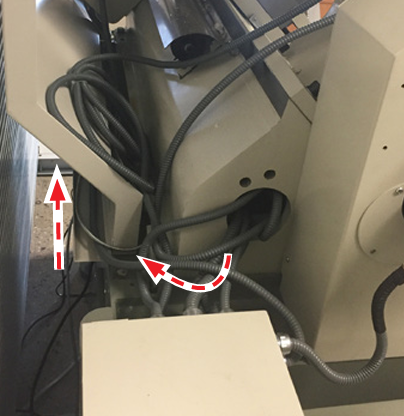

Following the X-axis motor conduit toward the lathe bed (see Figure 4)

-

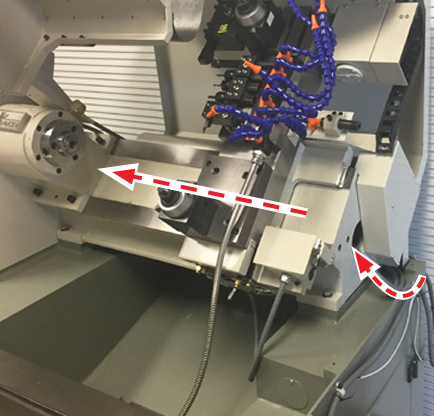

b. Through the access hole in the lathe bed casting toward the spindle (see Figure 5)

c. Through the opposite access hole in the lathe bed casting toward the back of the lathe (see Figure 6)

d. Toward the manual oiler installed on the stand along the back of the lathe

-

Connect oil line to manual oiler.

-

Using four M5 x 10 mm screws, mount Tubing Clips to pre-drilled holes and insert oil line; discard two surplus M5 x 10 mm screws.

-

Fill manual oiler reservoir with ISO VG68 Machine Oil (PN 31386) or similar.

Retract and release plunger until oil is pushed through system. After that, pull plunger:

-

Each time lathe is powered on

-

Every four hours of operation

-

Reinstall the access panel to the right side of the machine’s enclosure using the 16 screws that you set aside earlier.

Looking for more information?

This is a section of the 15L operator's manual. To view the whole manual, go to Tormach document UM10225.

If you have additional questions, we can help. Create a support ticket with Tormach Technical Support at tormach.com/how-to-submit-a-support-ticket for guidance on how to proceed.