Before you begin machining operations, you must setup and align the machine. Complete the following steps in the order listed:

Level the Machine

Before operating the machine, you must verify that it's approximately level. While this helps with things like coolant flow, it doesn't impact machine performance.

To level the machine:

-

Make note of any high or low spots, and, if required, adjust the leveling feet.

Install the Coolant Screen

-

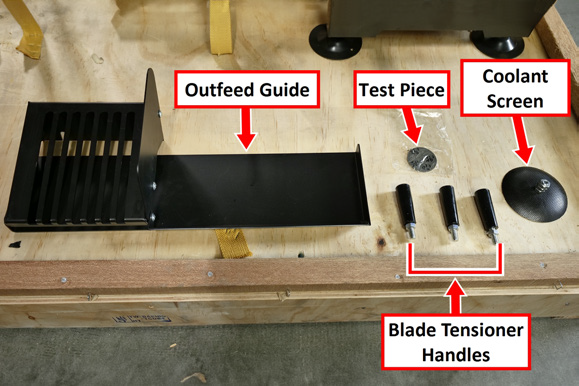

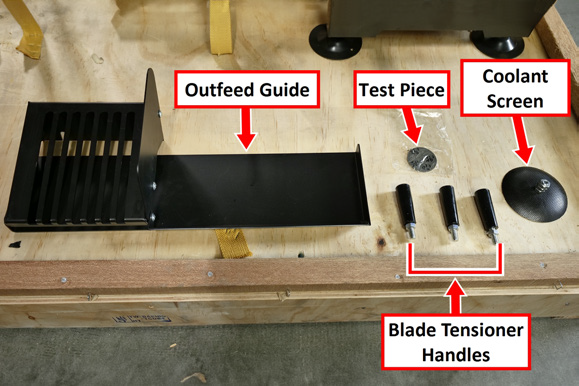

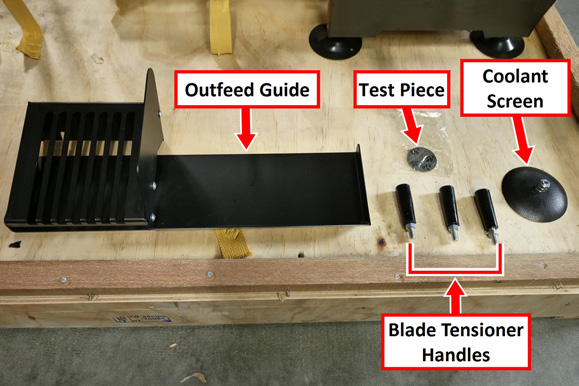

Find the accessory box that you set aside earlier. Remove the coolant screen from the box, and set the rest aside.

-

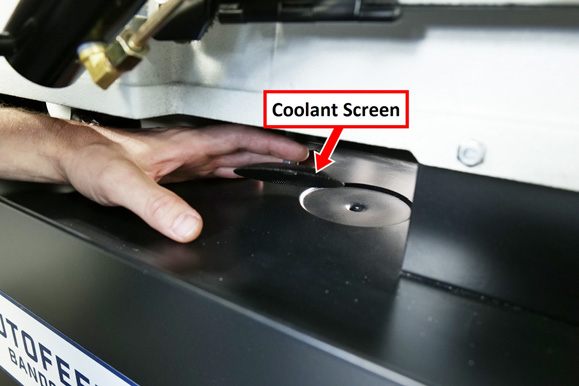

Put the coolant screen on the machine's base below the saw, as shown in the following image. Make sure that the nut on the coolant screen is facing up.

NOTE: The bolt on the coolant screen is intended to use as a handle.

Install the Blade Tensioner Handles

-

Find the accessory box that you set aside earlier. Remove the three blade tensioner handles from the box, and set the outfeed guide aside.

-

Install the three blade tensioner handles with a flat-blade screwdriver.

Install the Outfeed Guide

-

Find the outfeed guide (from the accessory box) that you set aside earlier.

-

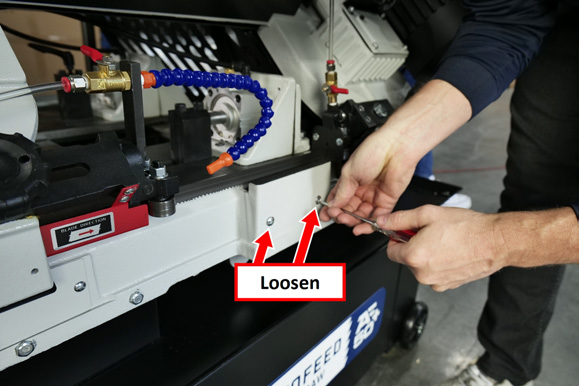

Identify the two Phillips head screws that are pre-installed on the machine. Loosen the screws with a Phillips head screwdriver.

-

Slide the outfeed guide over the two screws. Adjust the return tray so that it's in the pan, as shown in the following image.

-

Tighten the two Phillips head screws with a Phillips head screwdriver.

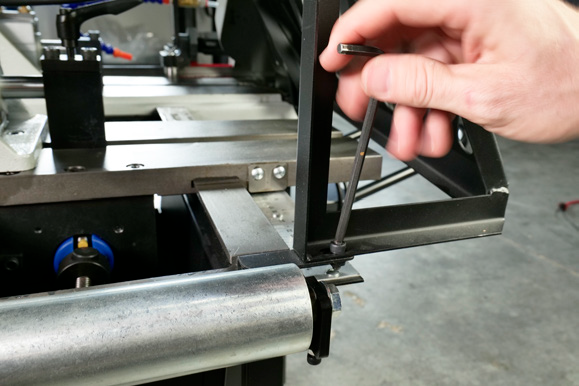

Remove the Shipping Bolts on the Rear Cage

-

The rear cage is secured to the frame for shipment. Remove the two bolts with a 5 mm hex wrench.

Verify Motor Belt Tension

To properly validate the installation of your machine, you must verify that the motor belt is properly tensioned.

To verify the motor belt tension:

-

Verify that the air supply and the machine's main power cable aren't yet connected to the machine.

-

Open the pulley cover.

-

Firmly push the belt between the pulleys. If it's properly tensioned, the belt should move approximately 1/2 in. If it's not properly tensioned, complete the steps in “Change the Speed”.

-

Close the pulley cover.

Make Air Connections

-

Remove the fitting from the input port on the FRL Filter-Regulator-Lubricator (on the back of the machine) with an adjustable wrench.

-

Install the provided fitting to the input port on the FRL with an adjustable wrench.

Connect the air line from your site to the input port on the FRL Filter-Regulator-Lubricator.

Air Requirements

-

Air Pressure 90-120 psi (620-825 kPa)

If the air supply is more than 120 psi (825 kPa), you must use a regulator. -

Dry Air We recommend using a compressed air dryer, desiccator, or filter between the air compressor and the machine.

-

Lubricated Air You must lubricate the air with air tool oil.

Looking for more information?

This is a section of the AF50+ Autofeed Bandsaw operator's manual. To view the whole manual, go to Tormach document UM10825.

If you have additional questions, we can help. Create a support ticket with Tormach Technical Support at tormach.com/how-to-submit-a-support-ticket for guidance on how to proceed.