Your machine axes require power and control signals to work. If either of those are disrupted you can lose any or all of your axes motion. If only one motor is not working go to, One Axis Won't Move (or Only Moves in One Direction), and Other Axes Move - 1300PL

Tools

-

Digital Multimeter

-

Metric Allen Keys

-

Small Flat Blade Screw Driver

Reseat the Connectors on the ECM Board and Motors

Reason: Control signals aren't reaching the electronic driver modules/servo motors.

-

Inspect the motor lights and the stepper driver controller.

-

Some lights are on (Applies to X and Y): One Axis Won't Move (or Only Moves in One Direction), and Other Axes Move - 1300PL .

-

All the lights are off (Applies to X and Y): Continue to the next step.

-

-

Power off the machine.

-

Examine the data cables at the machine control board and the servos/motor removing then re-connecting them to ensure they are seated.

-

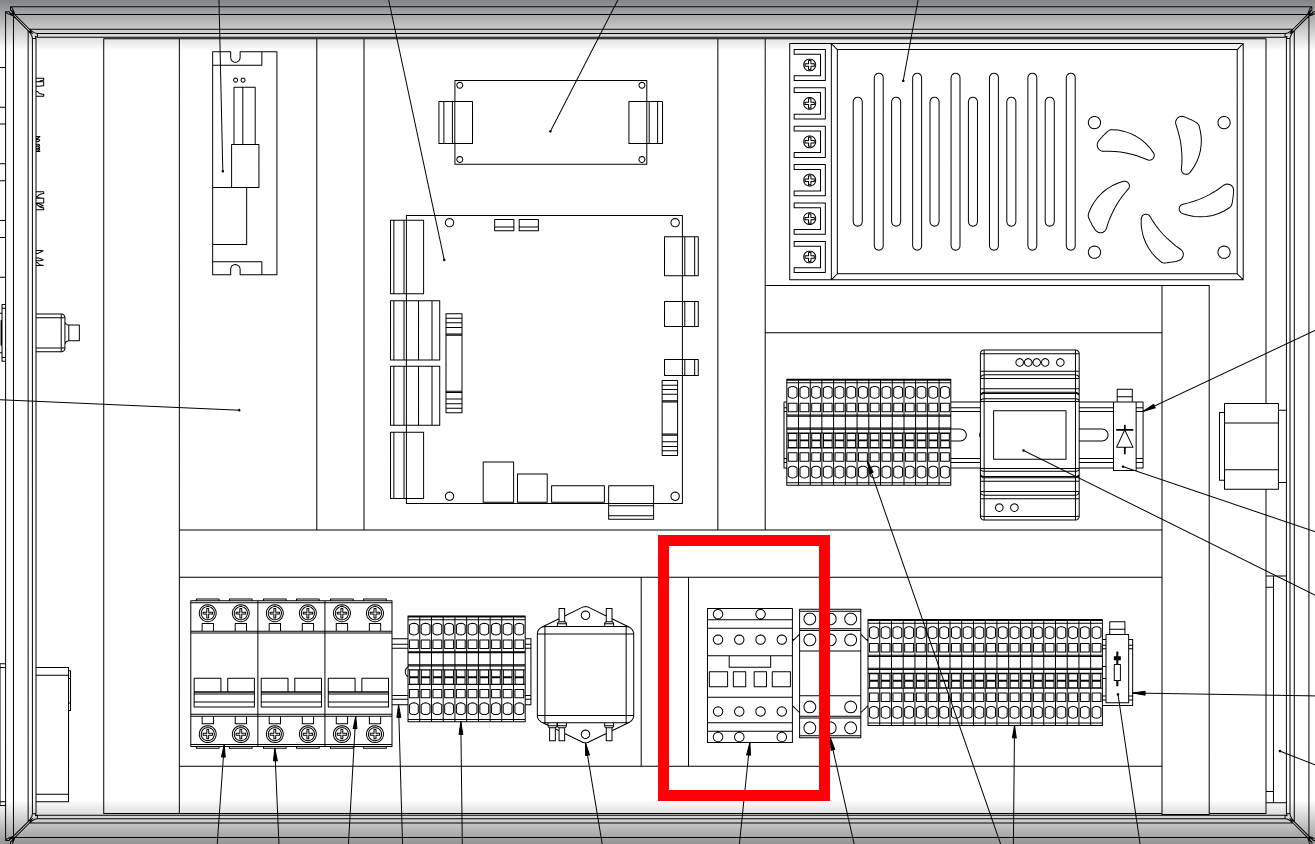

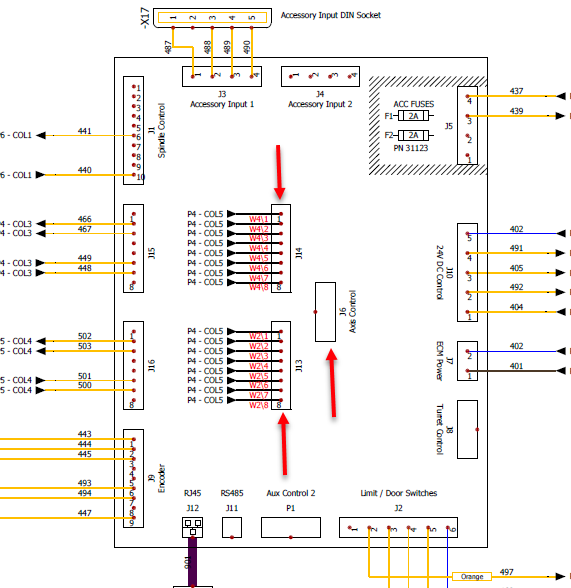

Machine control board: Degson style (X and Y) and 26 pin IDC (Z ribbon cable)

-

(J13) (X-axis)

-

(J14) (Y-axis)

-

(J6) (Z-axis)

-

-

Servos: Molex style

-

Stepper driver controller: 10 pin IDC (ribbon cable)

-

-

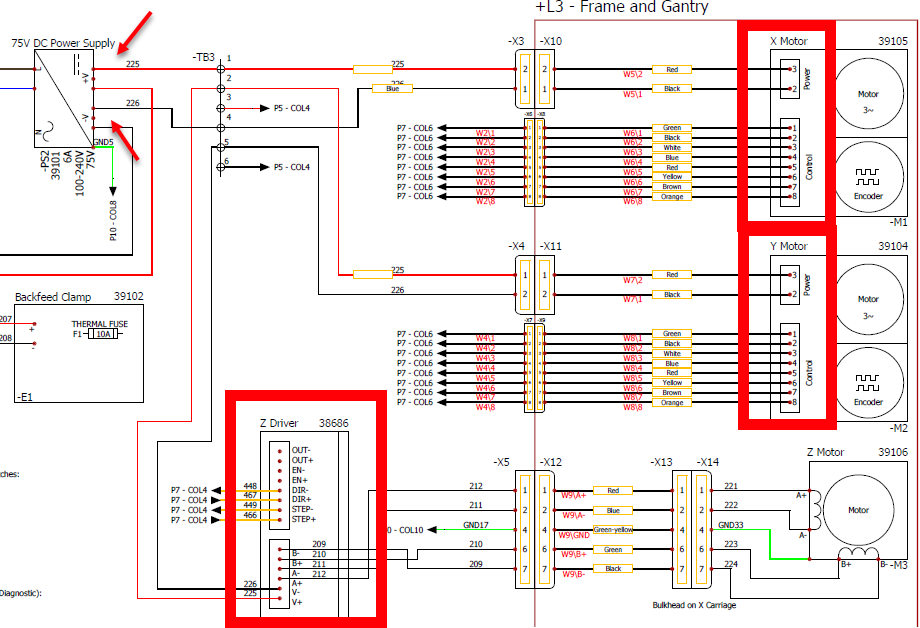

Examine the power cables at the DC Power supply and the servos/motor removing then re-connecting them to ensure they are seated.

-

DC Power Supply:

-

225/226 (X-, Y-, and Z-axis)

-

-

Servos: Molex style

-

Stepper: Degson style

-

209, 210, 211, 212, 225, and 226 (Z-axis)

-

-

-

Continue to the next troubleshooting topic.

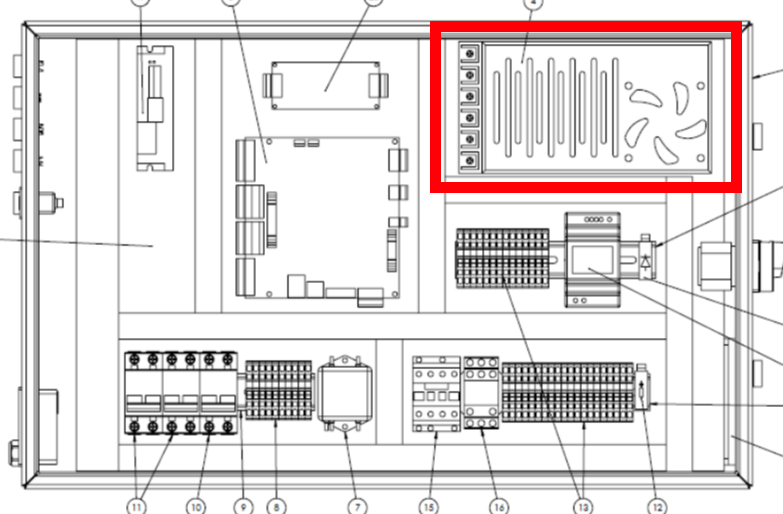

Inspect the DC Power Supply

Reason: The DC power supply is malfunctioning.

-

Inspect the DC power supply for power by determining if the green power light is illuminated.

-

If it does: The stepper driver controllers will be illuminated.

-

If it doesn’t: Continue to the next step.

-

-

Ensure the machine is powered on the machine and measure the Vac entering the DC power supply on:

-

116/N

-

115

-

-

Continue to the next troubleshooting topic.

Inspect the Controller and Machine Communication

Reason: PathPilot isn’t commanding the move, there is a cable problem, or a controller problem.

-

Power on the machine and take it out of reset.

-

Verify that the selected machine configuration in the bottom right corner of PathPilot is correct.

-

Select the Main tab, then, on the keyboard, press the Esc key.

-

Jog the axes and, from the PathPilot interface, examine the value displayed in their DRO fields.

-

If the position doesn't change: There's a problem with the controller.

-

If the position changes: There is a communication or hardware issue.

-

-

Continue to the next troubleshooting topic.

Check the K2 Contactor

Reason: The K2 is defective.

-

Power on the machine and take it out of reset.

-

Inspect the K2 to see if the center bar has been pulled in.

-

If bar is in: The K2 is latched. Using a digital multimeter set to Vac, measure for 220 Vac between:

-

116N

-

115

-

-

-

Press and hold the Reset button on the operator box and observe the K2. Then release the Reset button and observe the K2.

-

If the bar only stays in when the button is pressed: There is a loose coil wire, short, or the K2 has malfunctioned.

-

If the bar never gets pulled in: Go back to the previous troubleshooting topics to ensure your machine is receiving power.

-