Background

Your machine axes require power and control signals to work. If either of those are disrupted you can lose any or all axis motion. If all of your motors are not working, go to All Axes Won't Move When Commanded - 1300PL.

Tools

-

Digital multimeter

-

Small flat-bladed screwdriver

-

Metric hex wench set

-

Phillips screwdriver

Reseat the Connectors on the ECM Board and Motors

Reason: Control signals aren't reaching the electronic driver modules/servo motors.

-

Power off the machine

-

Examine the data cables at the machine control board and the servos/motor removing then re-connecting them to ensure they are seated.

-

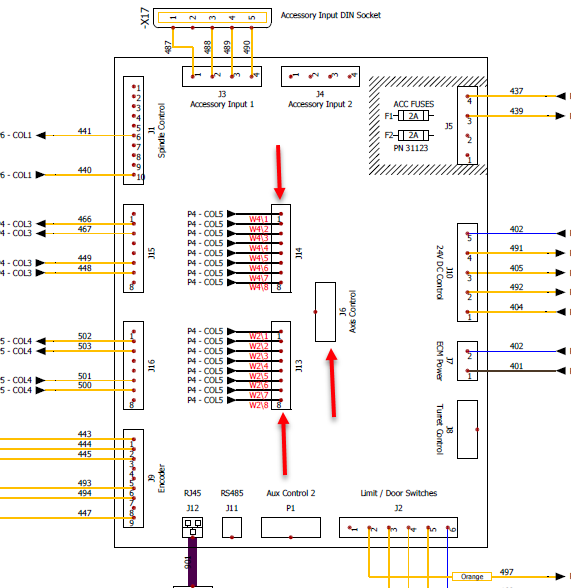

Machine control board: Degson style (X and Y) and 26 pin IDC (Z ribbon cable)

-

(J13) (X-axis)

-

(J14) (Y-axis)

-

(J6) (Z-axis)

-

-

Servos: Molex style

-

Stepper driver controller: 10 pin IDC (ribbon cable)

-

-

Examine the power cables at the DC Power supply and the servos/motor removing then re-connecting them to ensure they are seated.

-

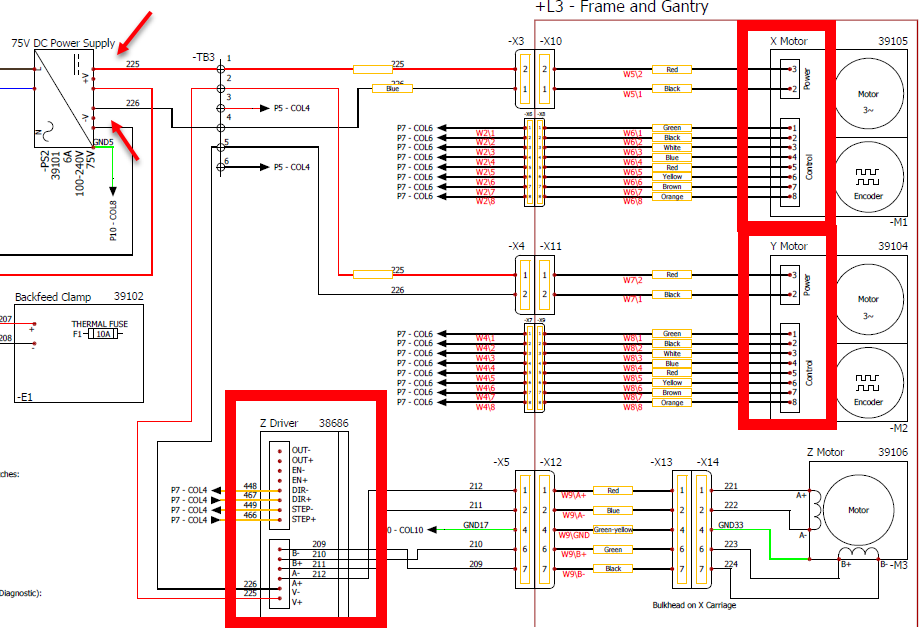

DC Power Supply:

-

225/226 (X-, Y-, and Z-axis)

-

-

Servos: Molex style

-

Stepper: Degson style

-

209, 210, 211, 212, 225, and 226 (Z-axis)

-

-

-

Continue to the next troubleshooting topic.

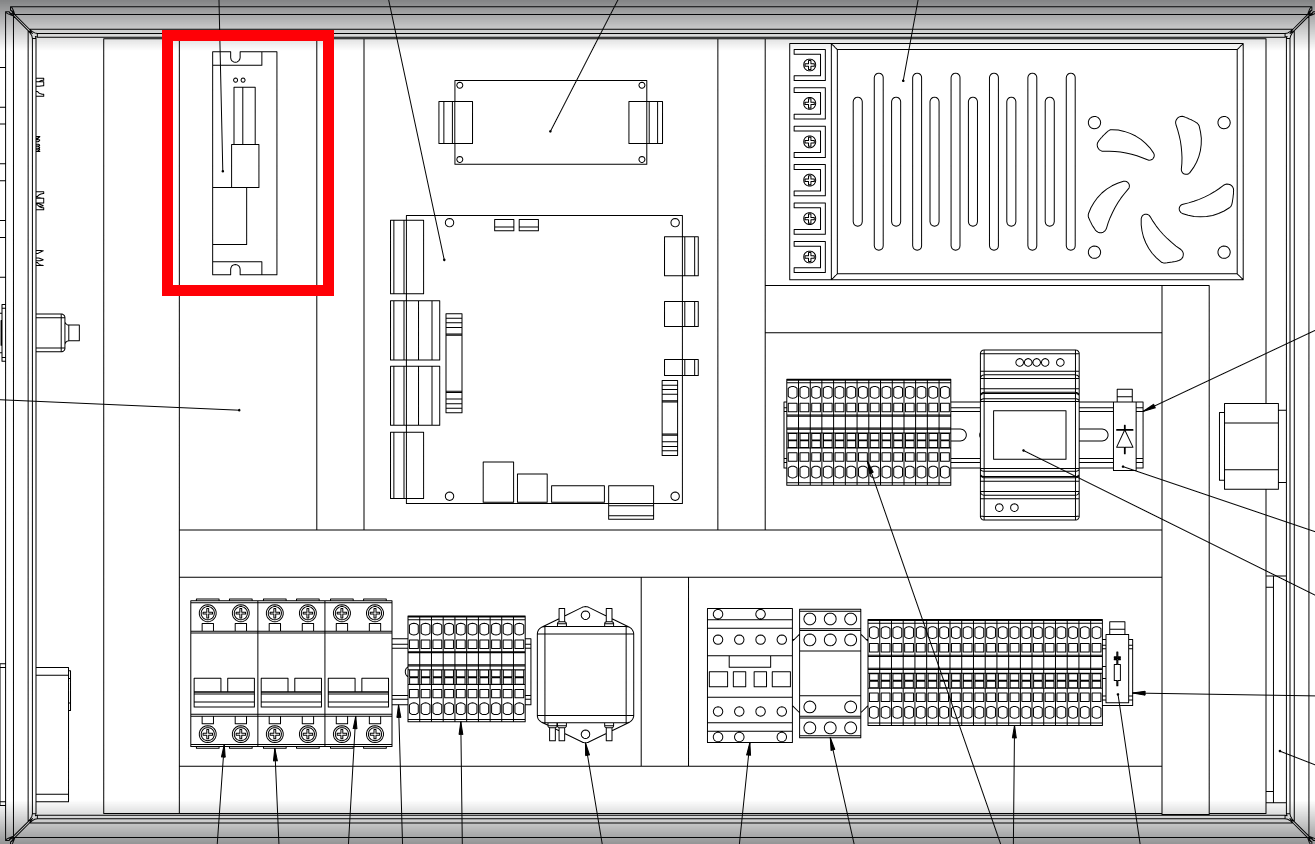

Inspect the Z Motor Driver

Assess the state of the motor or stepper driver controller

Reason: There's a defective or malfunctioning axis driver/cable.

-

Power on the machine and take it out of reset.

-

Examine the LEDs of the stepper driver controllers.

-

If the stepper driver controller has an illuminated green light: It is ready and operating normally.

-

If the stepper driver controller has an illuminated red LED: The machine should be power cycled to try and reset the stepper driver controller or the stepper driver controller needs to be replaced.

-

If the is no light on the stepper driver controller: Continue to the next troubleshooting topic.

-

Inspect the DC Power Supply

Reason: The DC Power Supply is faulty.

-

Inspect the DC power supply for power by examining if the green power light is illuminated.

-

If it does: The stepper driver controllers or motors will be illuminated.

-

If it doesn’t: Go to All Axes Won't Move When Commanded - 1300PL.

-

Inspect the Z Motor

Reason: There's a defective motor or motor connection.

-

Power off the machine.

-

Remove the motor leads from the axis stepper driver controller, and examine the degson connection for any burning or debris.

-

If there is burning or debris: Clean debris first, and retry. If it still fails, or any burning is present, replace the driver, and possibly the motor cable’s.

-

If no burning or debris: Continue to the next step.

-

-

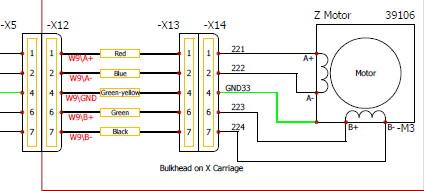

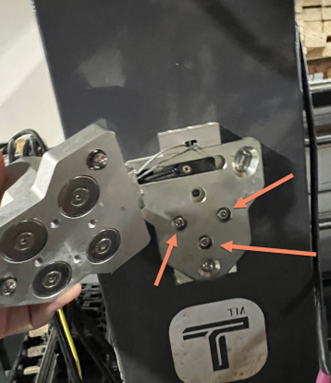

With machine power still off, remove the Z stepper motor power plug from the X gantry bulkhead. Identify Pin 1, 2, 6, and 7.

a. Measure the resistance between 221-222 and 223-224.

-

You should ideally see between 0.5-2.0 Ω.

-

If the resistance is out of spec: Then the motor is defective.

-

If the resistance is within spec: Then inspect the cable and connectors between the axis motor and axis driver. This includes measuring resistance from the X gantry bulkhead all the way to the Z axis driver.

-

Inspect the motor coupling

Reason: There's a loose axis motor coupling.

-

Jog the axis and listen to determine if you can hear the motor run.

-

Remove the cover plate over the coupling and make witness marks across the coupling and lead screw.

-

Jog the axis to determine if the motor's turning but the screw isn't.

-

If the coupling is slipping, locate the hex screws and tighten them down.

-

Tension or Replace the Axis Belt (Y Axis only)

Reason: The belt is too loose or it’s broken.

See Adjust Belt Tension.