In This Section, You'll Learn:

About the site requirements of this machine (including electrical and power requirements).

Before operating the machine in any way, you must read and understand this section.

General Site and Space Requirements

When choosing a location for your machine, you must verify that it meets all requirements outlined in this section.

Site Requirements

You must verify that the area:

-

Allows for unrestricted access to machine controls.

-

Conforms to the following:

-

Primary Power Required Single-Phase 230 Vac, 50/60 Hz

-

Recommended Circuit Amperage Dedicated 15 A breaker

-

NOTE: For more information, see "Electrical and Power Requirements".

-

Has a fire extinguisher within the work area.

-

Is a dry, properly ventilated, and well-lit internal space.

-

Provides for unobstructed machine motion and operation.

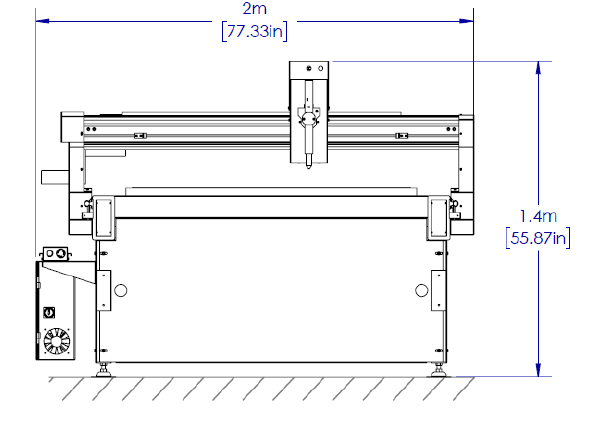

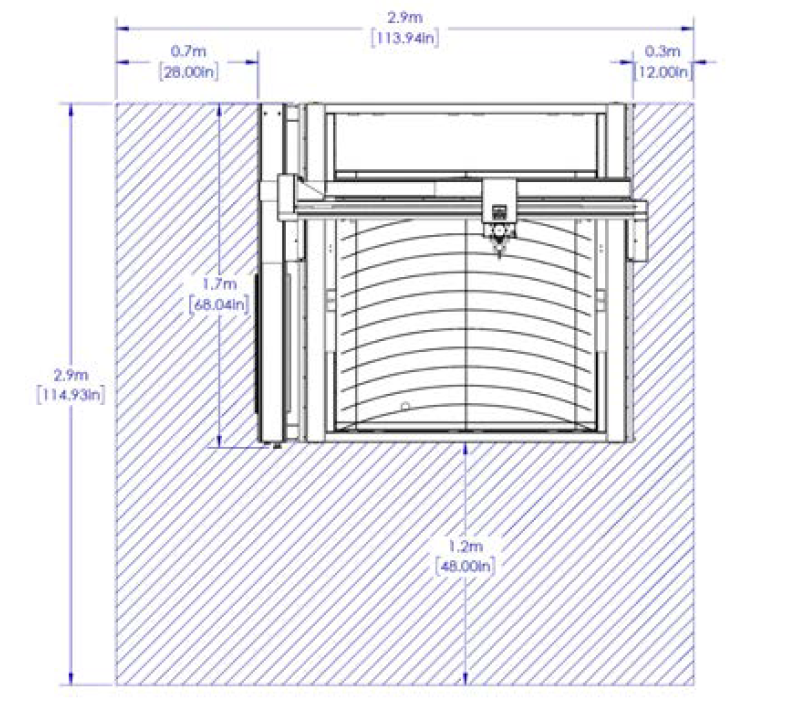

Space Requirements

The area must meet the following space requirements. Allow more space to access the rear of the machine for maintenance and repairs.

-

Machine Size 78" × 70" (1.95 m x 1.7 m)

-

Machine Height 55" (1.4 m)

-

Typical System Footprint 89" × 67" (2.3 m × 1.7 m)

Electrical and Power Requirements

You must verify that the site conforms to the following electrical and power requirements.

Electrical Requirements

A certified electrician must make all electrical connections, and it's your responsibility to verify that the electrical installation of the machine meets all local regulations and electrical codes.

-

Primary Power Required Single-Phase 230 Vac, 50/60 Hz

-

Recommended Circuit Amperage Dedicated 15 A breaker

Power Requirements

If the site conforms to the electrical requirements, verify that it meets the following power requirements:

-

Proper Grounding You must properly ground the power input to the machine. Examine the continuity between bare metal on the machine frame and true earth ground (a water pipe or similar) to verify that it's properly grounded.

-

Correct Plug Pattern The machine is shipped with a NEMA 6-20P plug, designed for use with a NEMA 6-20R receptacle.

Plasma Source Power Requirements

In addition to the requirements listed above for the machine itself, make sure that you have a separate circuit available to power your plasma source. For example, when using 220V single-phase power the Hypertherm Powermax 45 XP requires the following:

-

Primary Power Required 200 Vac – 240 Vac

-

Recommended Circuit Amperage 50 A

-

Plug Pattern NEMA 6-50P

Check with the manufacturer documentation for the specific plasma source you are using before installation.

Options for Non-Conforming Sites

For sites that don't conform to the specified "Electrical and Power Requirements", you may consider the following. You must consult with an electrician to determine the suitability for your site.

Buck-Boost Transformer Used to adjust line voltages. While the machine can run on line voltages between 200 to 240 Vac, performance is reduced on line voltages below 230 Vac, and damage to electrical components is possible on line voltages above 240 Vac. To prevent reduction in performance or damage to electrical components, we recommend the Buck-Boost Transformer (PN 32554).

Air Requirements

You must verify that the site conforms to the following air supply requirements.

-

Air Pressure 90-120 psi (620-825 kPa) If the air supply is more than 120 psi (825 kPa), you must use a regulator.

-

Air Volume At least 6 cfm at 90 psi. Check with your plasma source manufacturer in case your model requires more volume.

-

Dry Air We recommend using a compressed air dryer, desiccator, or filter between the air compressor and the machine.

Plasma Source Requirements

Tormach recommends either the Hypertherm Powermax 45 XP or the Powermax 65 plasma sources for use with the 1300PL. Plasma sources ordered directly from Tormach will include the correct CNC control interface and cables.

If you would like to use your own plasma source, the minimum

requirements are as follows:

-

Blowback style arc-start. The 1300PL is not recommended for use with high-frequency style arc-start units. The electrical noise spike generated by high frequency

arc starts can interfere with the axis control signals. -

An internal voltage divider outputting a 50:1 torch voltage signal.

-

An input for plasma arc start compatible with dry contact closure to activate (the 1300PL uses an open relay for torch off and closed relay for torch on)

-

(Optional but recommended) Arc-ok output. Closed contacts when arc is active.

Looking for more information?

This is a section of the 1300PL operator's manual. To view the whole manual, go to Tormach document UM10720.

If you have additional questions, we can help. Create a support ticket with Tormach Technical Support at tormach.com/how-to-submit-a-support-ticket for guidance on how to proceed.