Tools and Items Required

-

Hose or bucket

-

Plasma cutting fluid (rust inhibitor such as GreenCut or similar)

A properly filled water table is critical for safe operation of the 1300PL. The water table traps a majority of the metal particulates released in the cutting process and keeping it filled is important for maintaining good air quality in your shop space.

-

Ensure that the drain valve on the bottom of the water table is in the closed position.

-

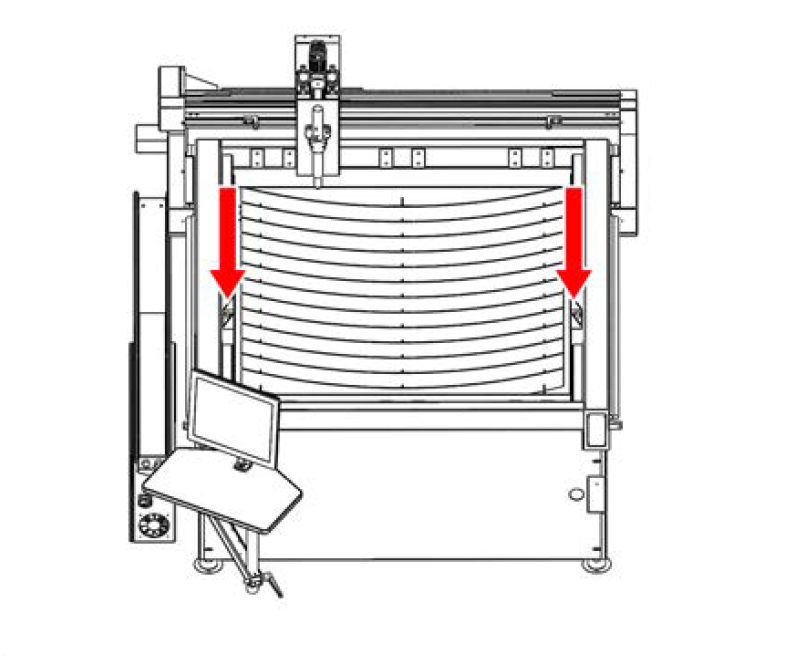

Check that the two lock bolts that hold the table in place on the front-to-back tracks are in place.

-

Using a hose or buckets, fill the table with tap water until the level is about 1" below the top of the slats.

-

Add cutting fluid to the water to inhibit corrosion. Use the ratio recommended by the cutting fluid manufacturer. For reference, full water table capacity on the 1300PL is 59 US gallons (223 liters).

-

Top the water table off to 0.5" below the top of the slats after adding cutting fluid if desired.

Looking for more information?

This is a section of the 1300PL operator's manual. To view the whole manual, go to Tormach document UM10720.

If you have additional questions, we can help. Create a support ticket with Tormach Technical Support at tormach.com/how-to-submit-a-support-ticket for guidance on how to proceed.