Background

The 24R ATC spindle has two different internal sensors. Below is a quick check to verify function of said sensors.

If your power draw bar or tool sensor do not change in the status page in PathPilot, your power drawbar sensors may be bad. Before you begin this test, please go into the status page and activate the power drawbar manually (with and without a tool) and ensure both statuses are not changing.

Check TPS Sensor

Reason: Bad sensor, bad harness, or bad board

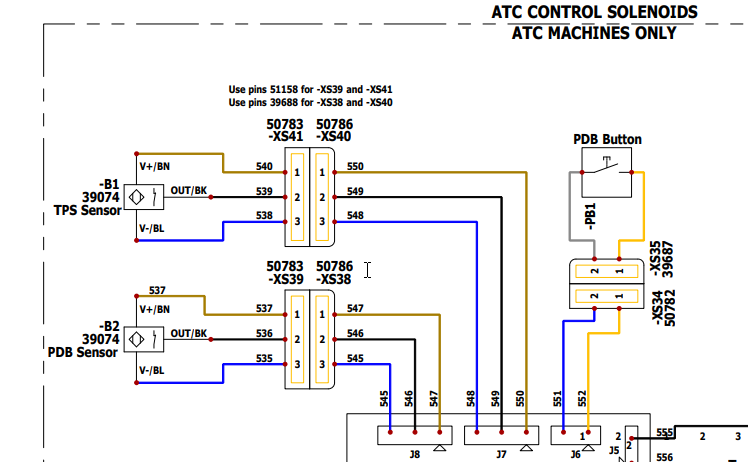

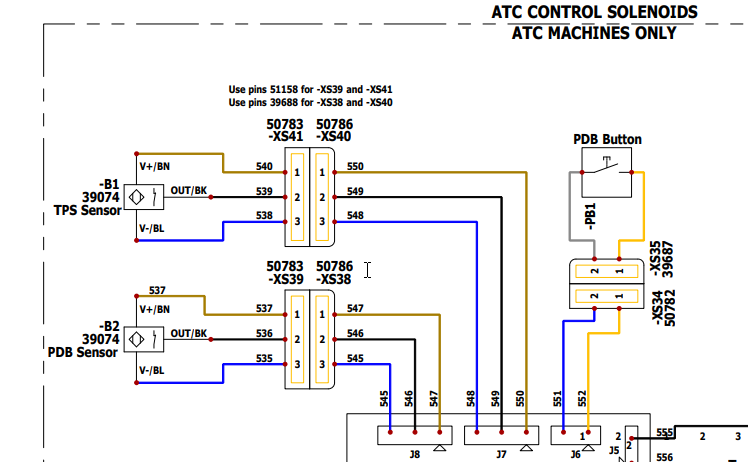

Locate wires 550, 549, and 548 at the quick connection above the spindle. Jump wires 550-549 at the harness leading to the board. Does the TPS light in the Status tab of PathPilot, change states? If so, the sensor is bad, or the wiring on the sensor itself is orientated incorrectly. If the light does not change states, jump these two wire locations on the ATC board itself. If the light still does not change states, verify “ATC board function”. A replacement may be needed.

Check PDB Sensor

Reason: Bad sensor, bad harness, or bad board

Locate wires 547, 546, and 545 at the quick connection above the spindle. Jump wires 547-546 at the harness leading to the board. Does the PDB light in the Status tab of PathPilot, change states? If so, the sensor is bad, or the wiring on the sensor itself is orientated incorrectly. If the light does not change states, jump these two wire locations on the ATC board itself. If the light still does not change states, verify “ATC board function”. A replacement may be needed.