Background

This 9 step document will help you isolate the cause of your lost motion. Follow the tests in order, and make sure each passes, before continuing on.

Tools

-

Dial Travel Indicator with Mag Base

-

Allen Wrenches

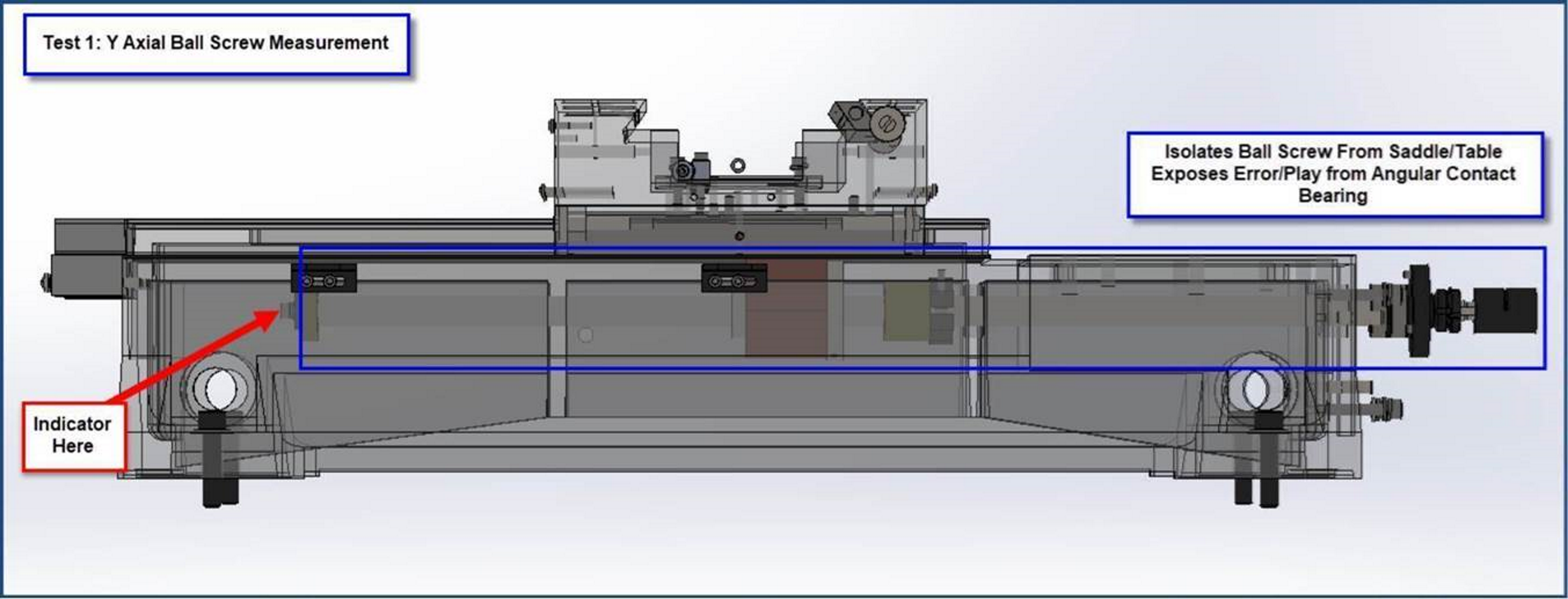

Test 1 - Y Axis Ball Screw Axial Test

Angular Contact Bearing Adjustment Procedure then proceed to Test 2.)

If motion is at .0003, proceed to Test 2

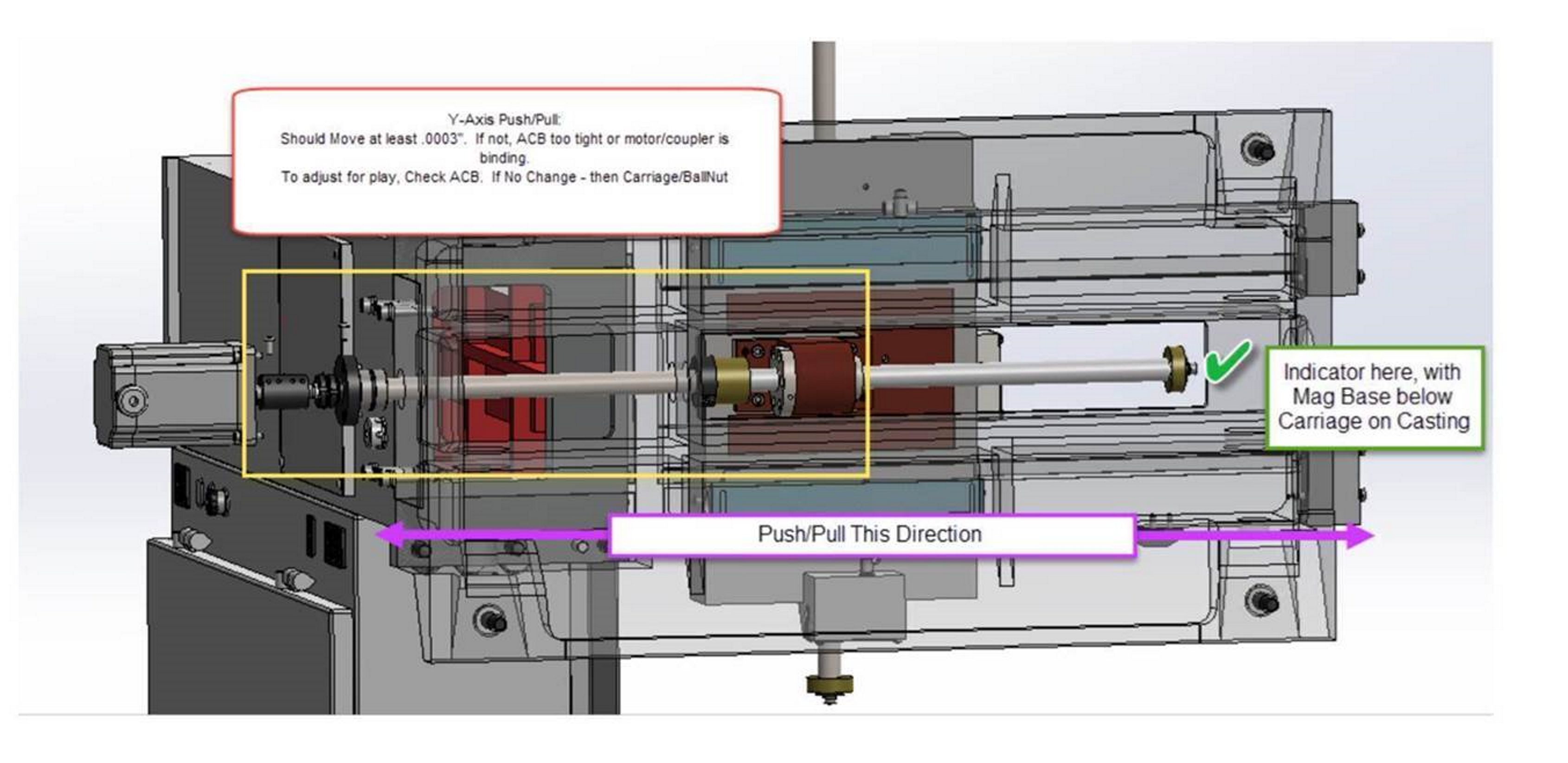

Test 2 - Y Axial Casting Measurement

Gib adjustment procedure to get to the .0007 – .001” range. (Accumulative/Stacked Tolerance is factored in here - assuming .0005” per previous two steps.)

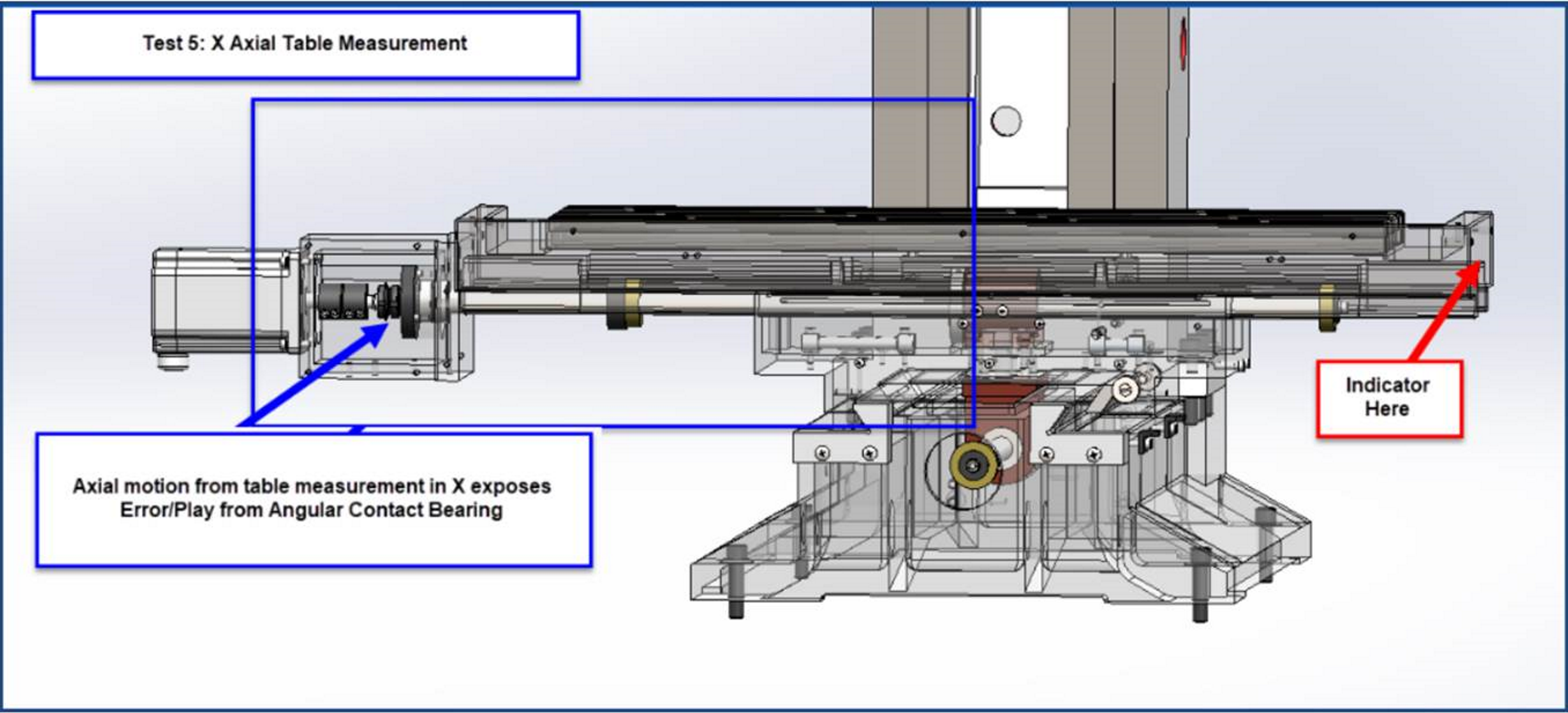

Test 4 - X Axial Ball Screw Measurement

Angular Contact Bearing Adjustment Procedure then proceed to Test 6.)

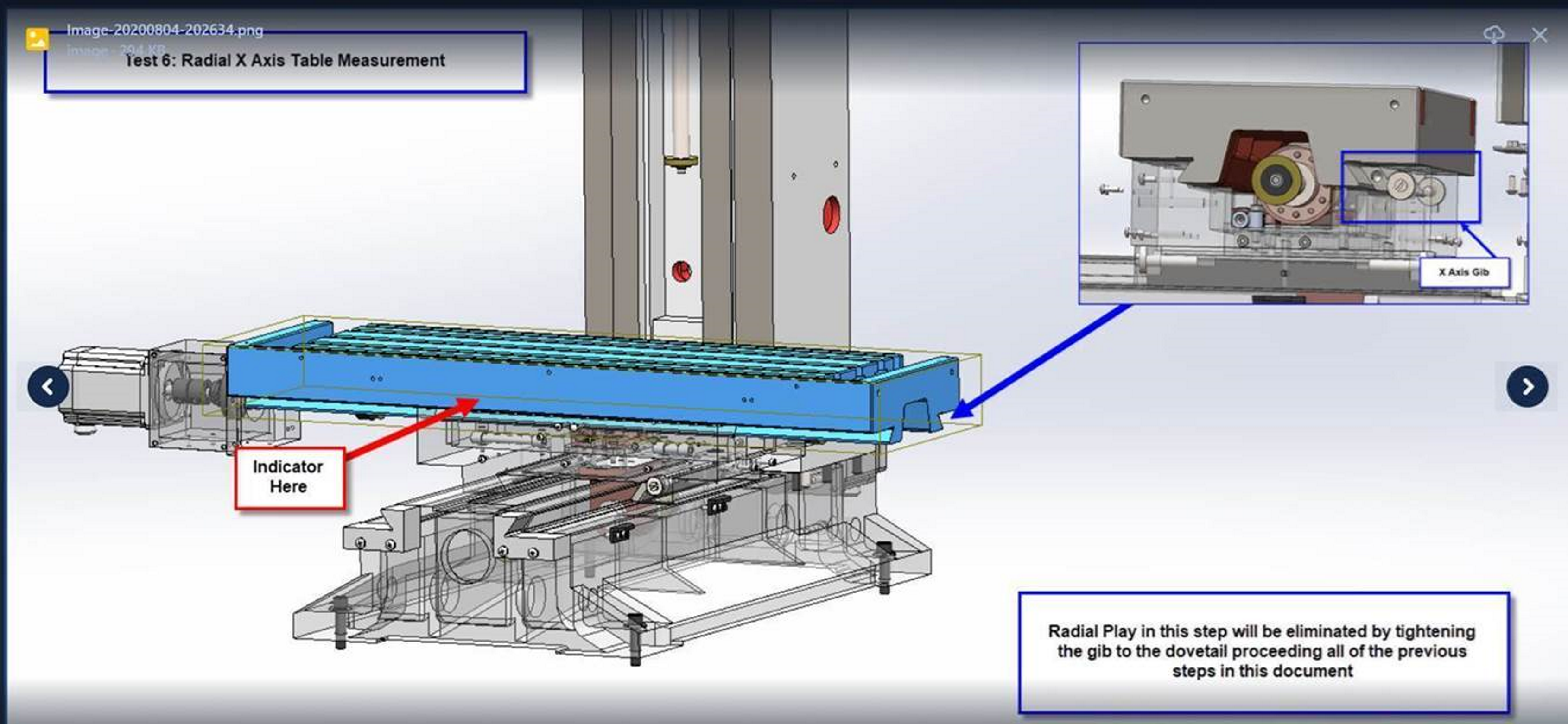

Test 6 - Radial X Axis Table Measurement

Gib adjustment procedure to get to the .0007 – .001” range. (Accumulative/Stacked Tolerance is factored in here - assuming .0005” per previous two steps.)

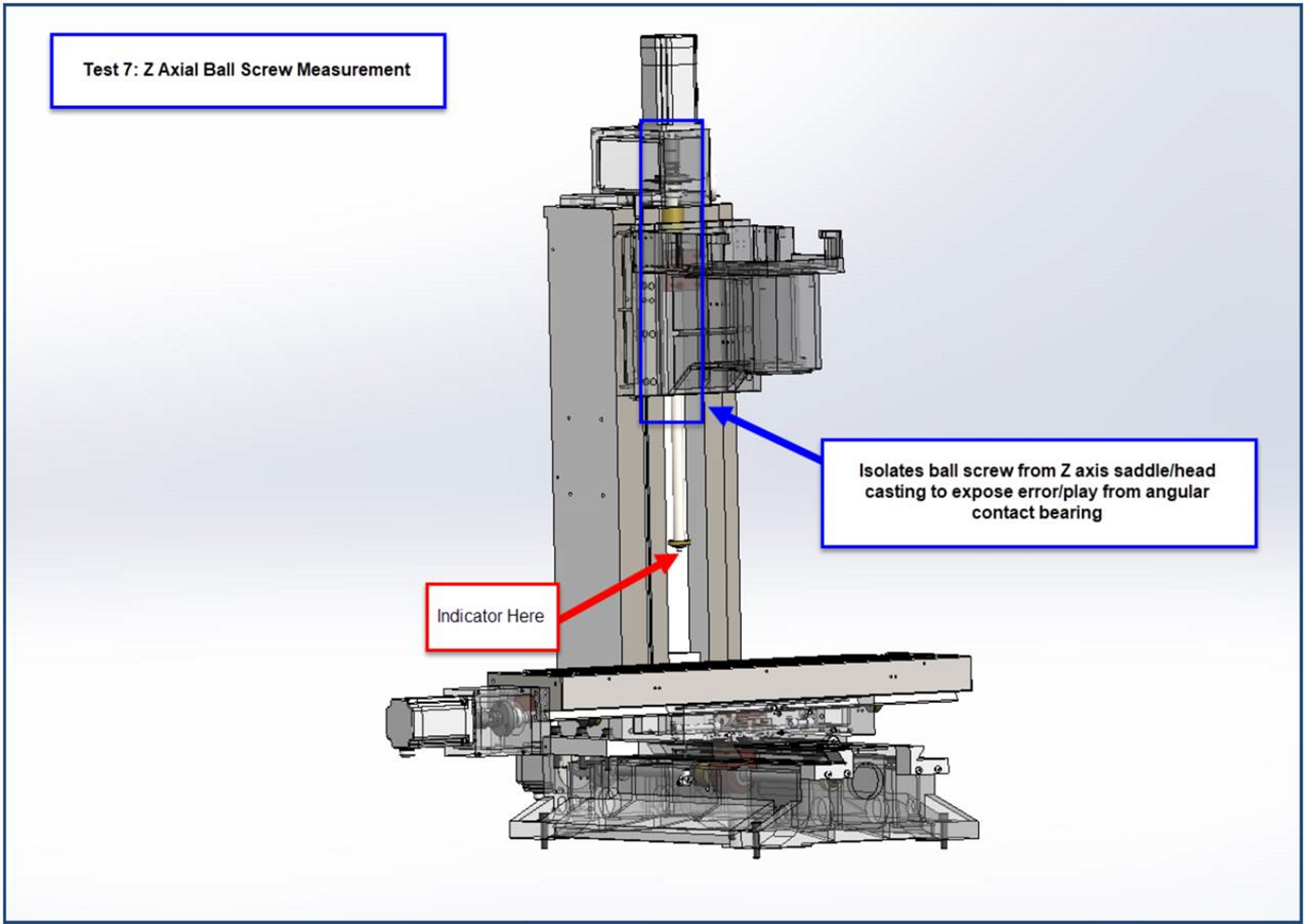

Test 7 - Z Axis Ball Screw Axial Test

Angular Contact Bearing Adjustment Procedure then proceed to Test 8.)

If motion is at .0003, proceed to Test 8.

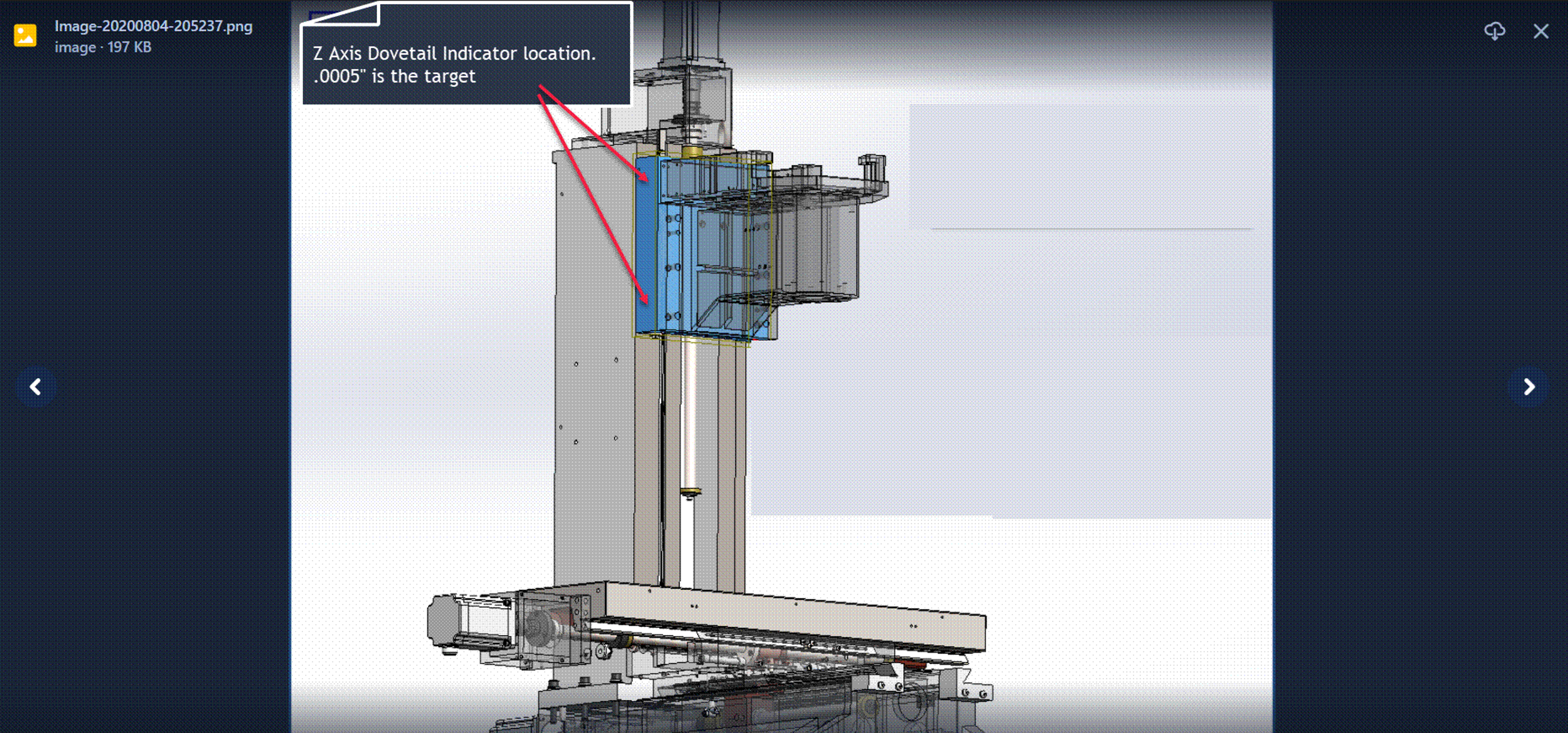

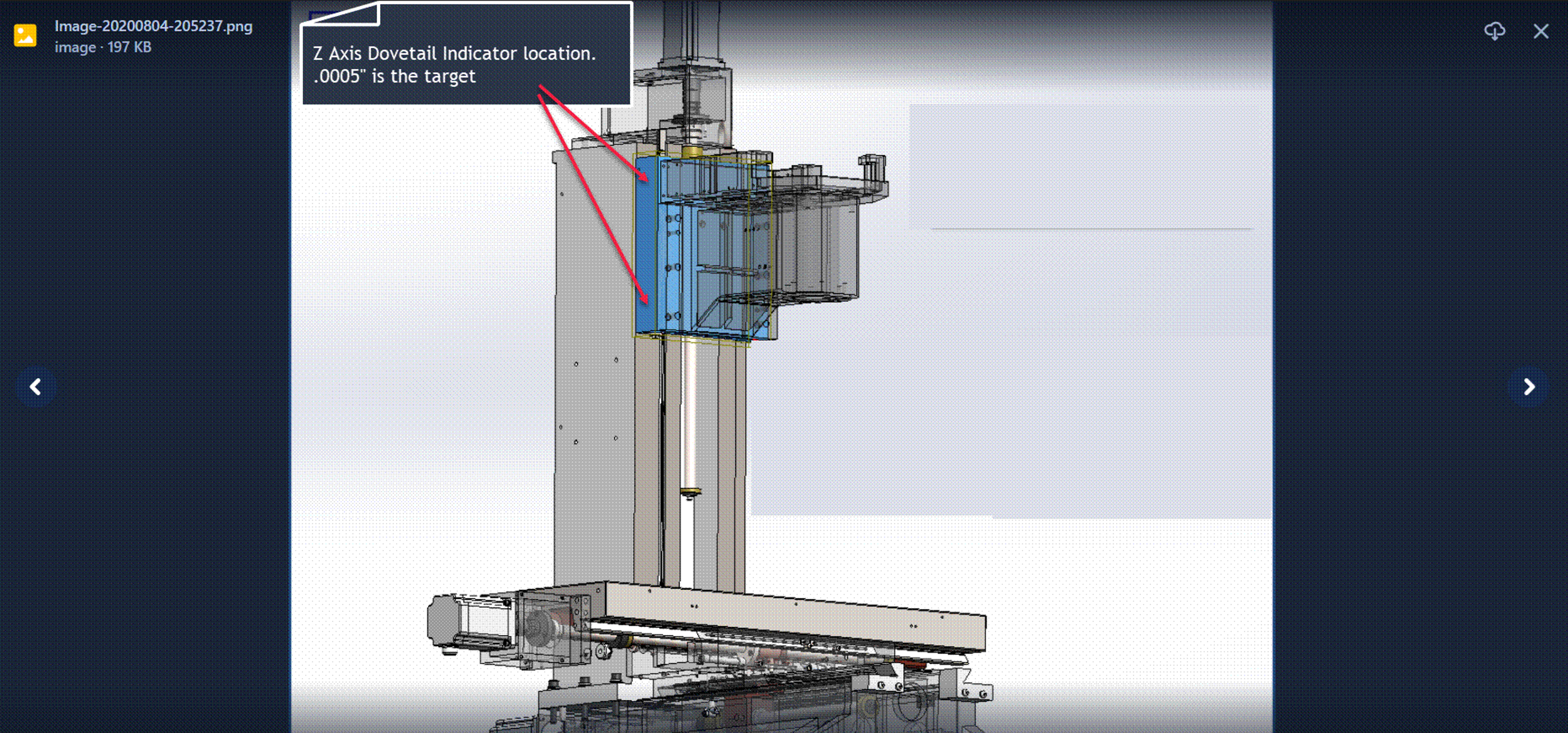

Test 8 - Z Axis Casting Axial Test

Gib adjustment procedure to get to the .0007 – .001” range. (Accumulative/Stacked Tolerance is factored in here - assuming .0005” per previous two steps.)

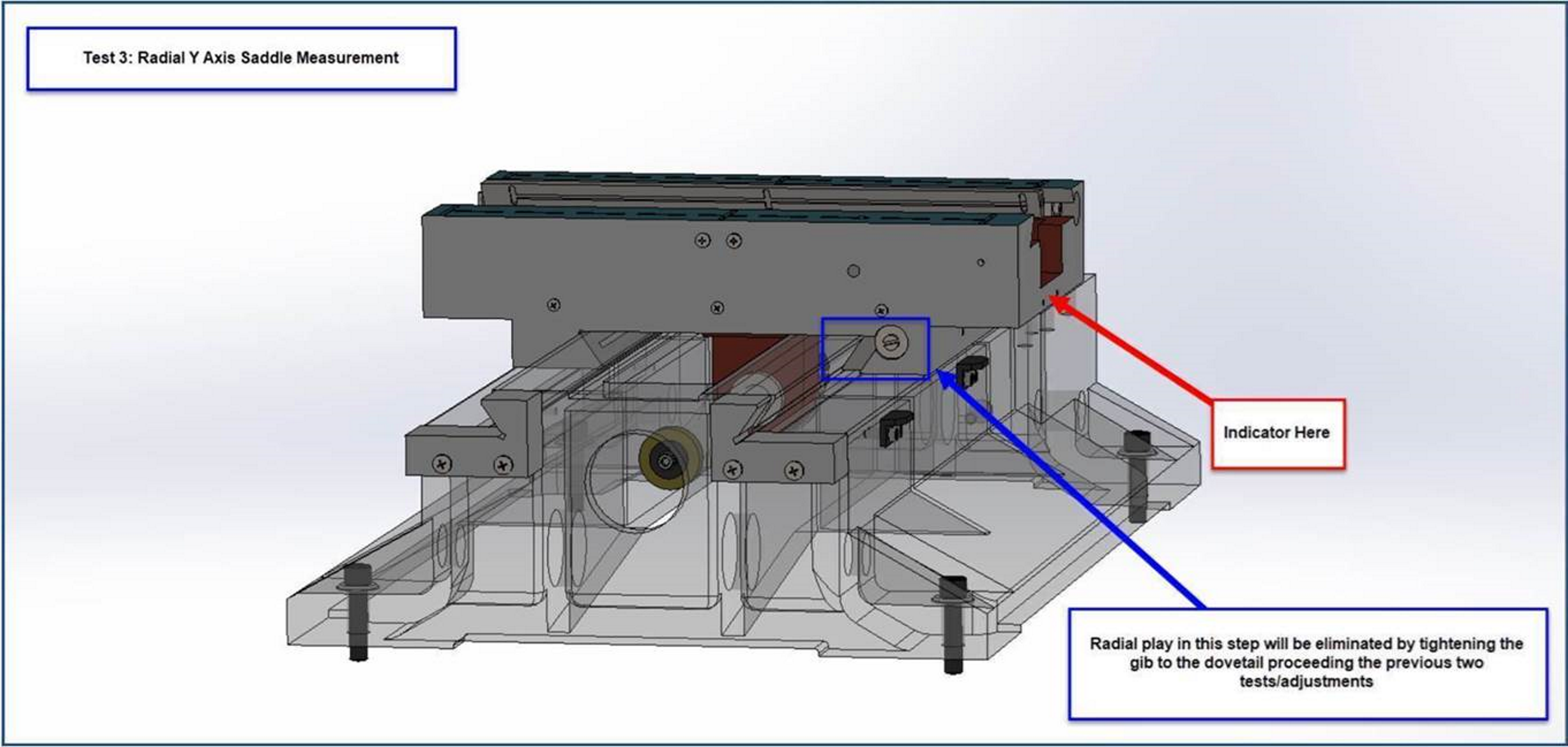

Test 9 - Radial Play in Z Axis Saddle

Move Indicator to spindle head and rock. Follow Gib adjustment procedure to get to the .0007 – .001” range. (Accumulative/Stacked Tolerance is factored in here - assuming .0005” per previous two steps.)