Background

The idea of providing power to your machine seems simple: just plug it in. In reality, there are a number of other components used in order to provide power appropriately safety for you and the machine, including (but not limited to):

-

The main disconnect switch

-

Fuses and/or circuit breakers

-

Emergency stop switch/button

-

Separate latching circuits for the spindle and rest of the machine

-

Transformers, which change the electricity to the appropriate value

Even with all of these components, you can systematically locate nearly any problem with just a multimeter.

Tools

-

Digital multimeter

Twist Out the Emergency Stop Button

Reason: The Emergency Stop button is pushed in.

-

Twist out the Emergency Stop button and press the Reset button.

The Reset button doesn't illuminate until after you:

-

Twist out the Emergency Stop button.

-

Press the Reset button.

Reset the Building’s Mains Breaker

Reason: The shop or building’s mains breaker is turned off.

-

Examine the building’s breaker. If it's not already on, turn it on.

-

Using a digital multimeter, measure to inspect and verify that you have power at the outlet.

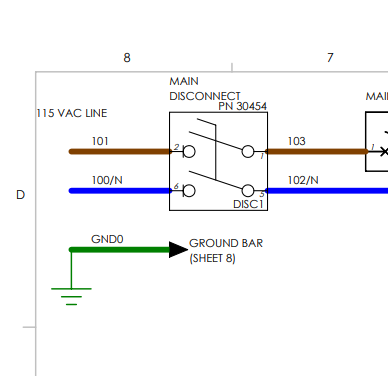

Inspect the Power Entering the Machine

Reason: The Main Disconnect switch is in the Off position.

-

Examine the Main Disconnect switch. If it’s not already in the On position, turn it on and try to take your machine out of reset.

-

Measure the voltage coming out of your Main Disconnect switch.

-

Identify the wires as indicated in the table.

-

If you measure the correct Vac, continue.

-

If you do not any Vac, you either have a loose wire or a faulty Main Disconnect switch.

-

|

Machine |

Wires |

Measure for… |

|---|---|---|

|

770M/MX |

101 and 100/N |

115 Vac nominal |

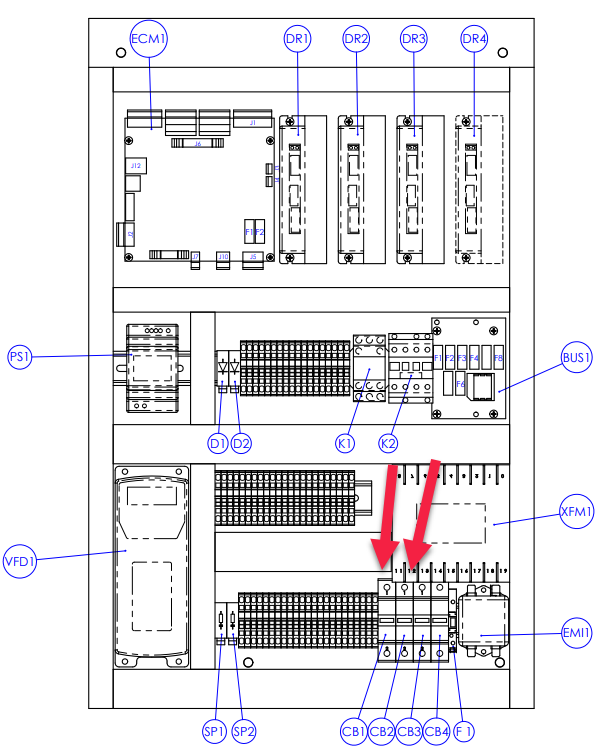

Reset the CB1 and/or CB2 Circuit Breaker

Reason: The CB1 and/or CB2 circuit breaker tripped.

-

Measure the wires as indicated below.

-

If required, power off the machine and reset the tripped breaker.

|

Machine |

Wires (CB1 and CB2) |

Measure for… |

|---|---|---|

|

770M/MX |

105 and 100/N and 107 and 100/N |

115 Vac nominal |

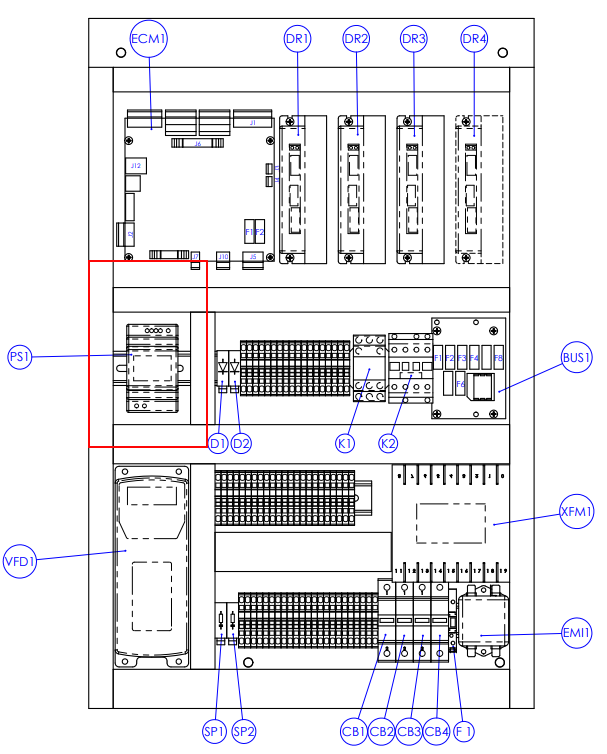

Inspect the DC Power Supply (PS1)

Reason: The DC power supply PS1 is defective.

-

With a multimeter measure the Vdc between 400 and 401.

-

If the digital multimeter reads below 22 Vdc, with a multimeter measure between 112/N and 113 for the input Vac.

If the input Vac is correct, replace the DC power supply.

|

Machine |

Wires |

Measure for… |

|---|---|---|

|

770M/MX |

400 and 401 |

24 Vdc nominal |

|

Machine |

Wires |

Measure for… |

|---|---|---|

|

770M/MX |

112/N and 113 |

115 Vac nominal |

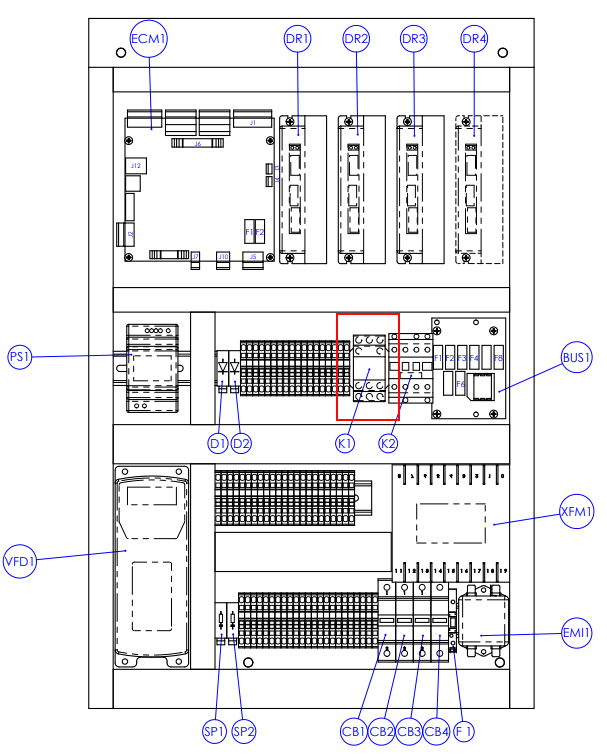

Inspect the K1 Contactor

Reason: The contactor K1 is defective.

-

Examine the K1 contactor’s red LED light. Depending on the state, do one of the following:

-

Red LED is On. This indicates that the contactor is latched. Use a digital multimeter to examine the power at K1-1 and wire 115.

-

Red LED is Off. Press and hold the Reset button and observe the LED on K1:

-

If it's on, K1 has a latching circuit issue.

-

If it's not on, K1 may have a coil issue.

-

-

Contactor K1 energizes the DC-BUS board, which provides 65 Vdc to the machine. K1 can fail by not energizing the coil, or the contacts could fail.