Background

As motors rotate and the machine cuts, vibrations are created. While these are normal, they can resonate, making it sound like something is wrong. Loose sheet metal won’t affect your machine performance, but there are other electrical and mechanical components that should be inspected if the noise doesn’t subside.

Tools

-

Small flat-bladed screwdriver

Secure Loose Sheet Metal

Reason: There is loose sheet metal.

-

Feel for vibration on the sheet metal by placing your hand on the enclosure, outside of the electrical cabinet, chip tray, or any other location you think is practical.

If the vibration dissipates then the problem is not with the motors.

Check the Foot Spacer

Reason: That machine’s foot spacer is loose.

-

Check that each foot spacer is tight against the base casting’s foot plates.

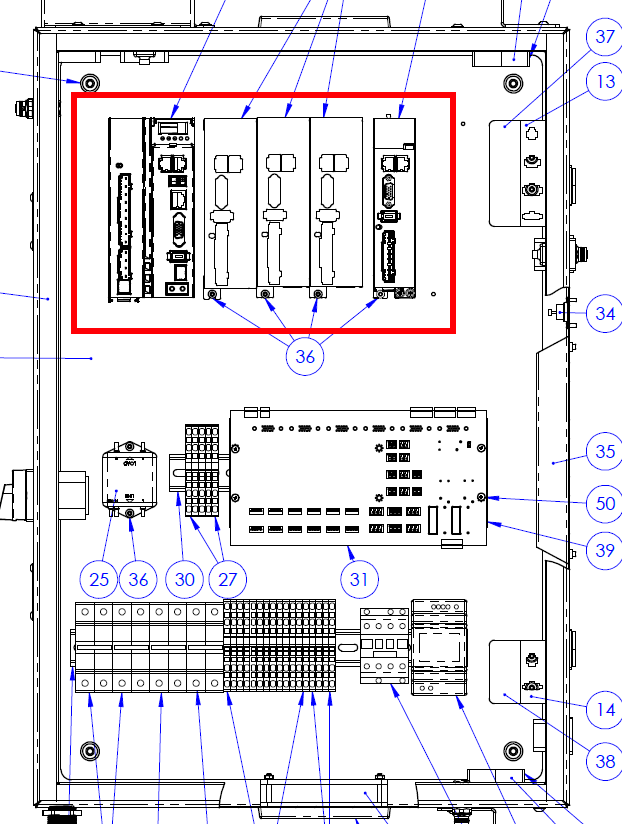

Check Driver Connections

Reason: There’s a loose wire connection or failed connector.

-

Power off the machine (see Verify the Installation | Power off the Machine). Then check all driver connections.

Troubleshoot Servo

Reason: There is a defective servo motor.

-

See “One Axis Won't Move (or Only Moves in One Direction), and Other Axes Move - 1500MX”

There have been cases of a noisy axis relating to a defective servo motor. This may be temperature-dependent.