Background

The idea of providing power to your machine seems simple: just plug it in. In reality, there are a number of other components used in order to provide power appropriately safety for you and the machine, including (but not limited to):

-

The main disconnect switch

-

Fuses and/or circuit breakers

-

Emergency stop switch/button

-

Separate latching circuits for the spindle and rest of the machine

-

Transformers, which change the electricity to the appropriate value

Even with all of these components, you can systematically locate nearly any problem with just a multimeter.

Tools

-

Digital multimeter

Reseat the NEMA L6-30 Plug Into an Outlet

Reason: The machine plug isn’t plugged in to an outlet.

-

Verify that the main power plug is plugged into a known working outlet.

-

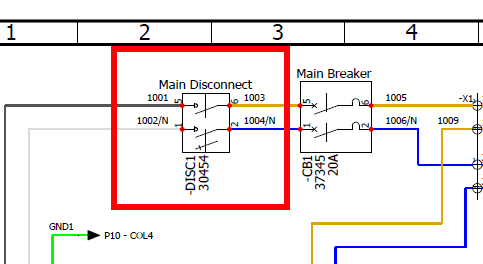

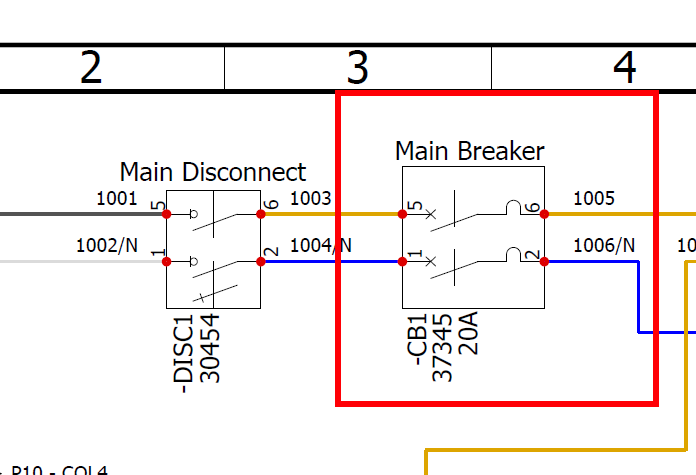

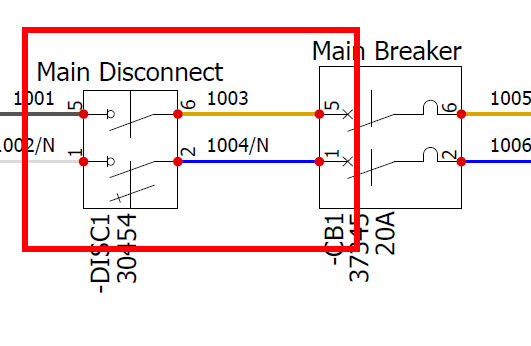

If needed, measure for 208-240 Vac between wires 1001 and 1002/N at the DISC1 Main Disconnect.

Reset Facility’s Breaker for Machine Circuit

Reason: The facility’s mains breaker is tripped.

-

Examine power cable for damage or exposed wires, and then reset your facility’s circuit breaker serving the machine.

-

If needed, measure for 208-240 Vac between wires 1001 and 1002/N at the DISC1 Main Disconnect. (See images above)

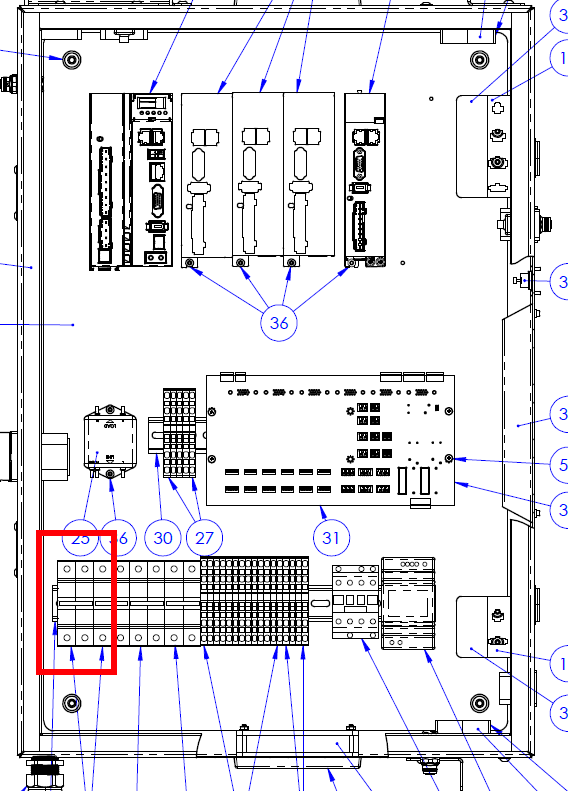

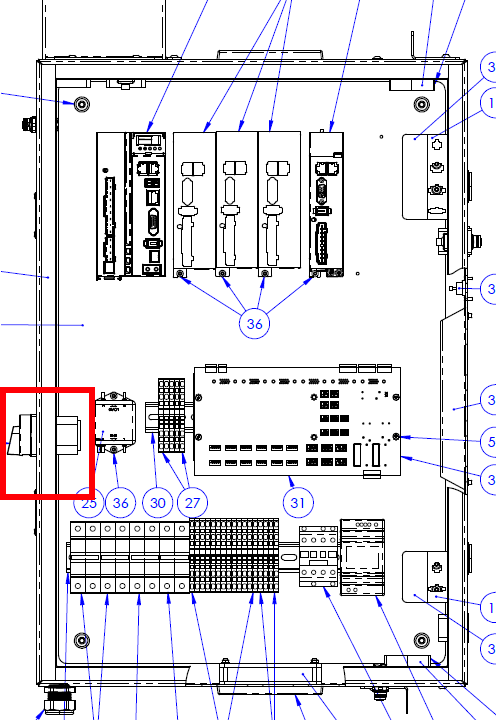

Reset the CB1 Circuit Breaker In the Machine

Reason: The CB1 breaker is tripped.

-

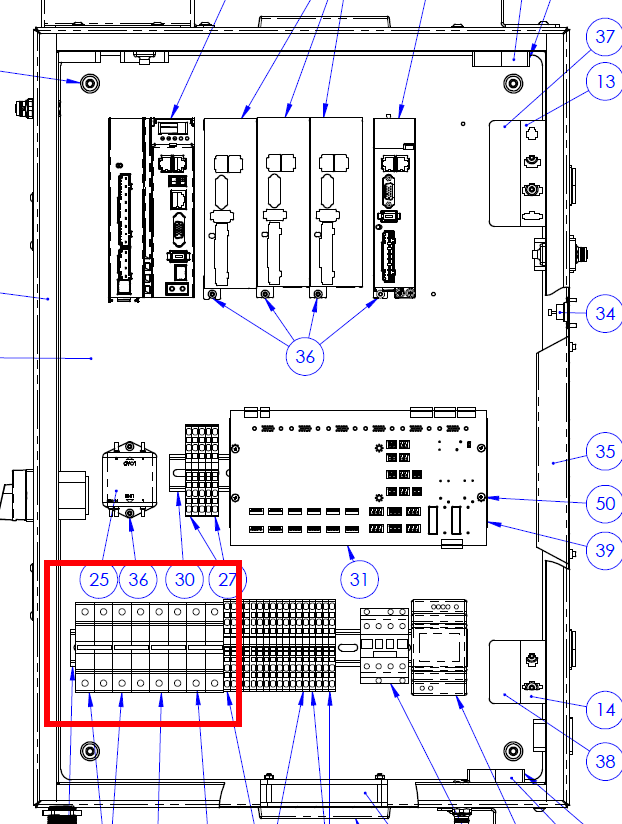

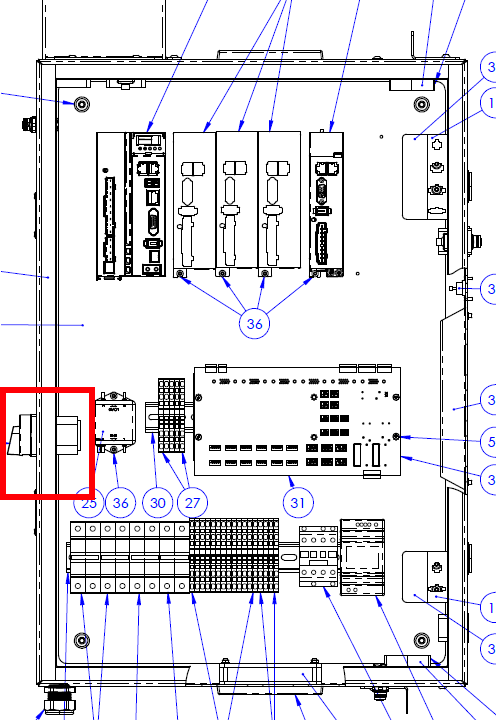

If the mill, controller, accessories, and enclosure lights don’t have power, examine the power cords and wires for damaged or exposed wires, and then reset the CB1 circuit breaker.

-

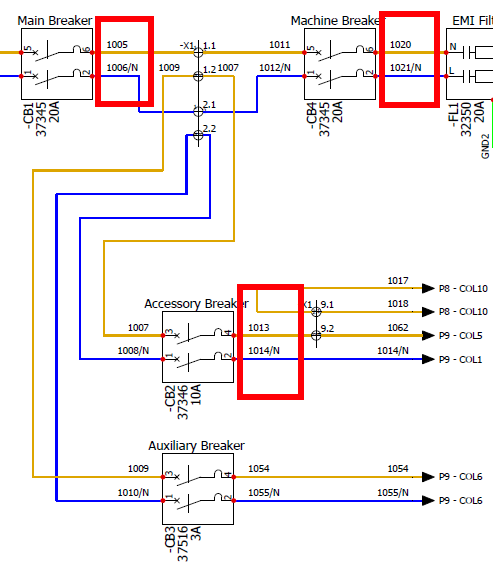

If needed, measure for 208-240 Vac between wires 1005 and 1006/N at the CB1 circuit breaker.

Check the Position of the Main Disconnect Switch

Reason: The Main Disconnect switch is in the OFF position.

-

Switch DISC1 Main Disconnect to the ON position.

-

If needed, measure for 208-240 Vac between wires 1003 and 1004/N at the DISC1 Main Disconnect.

Verify the Machine is Out of Emergency Stop Condition

Reason: The Emergency Stop is pushed in.

-

Twist out the Emergency Stop button and press the Reset button.

Check the DC Power Supply

Reason: The DC power supply is defective.

-

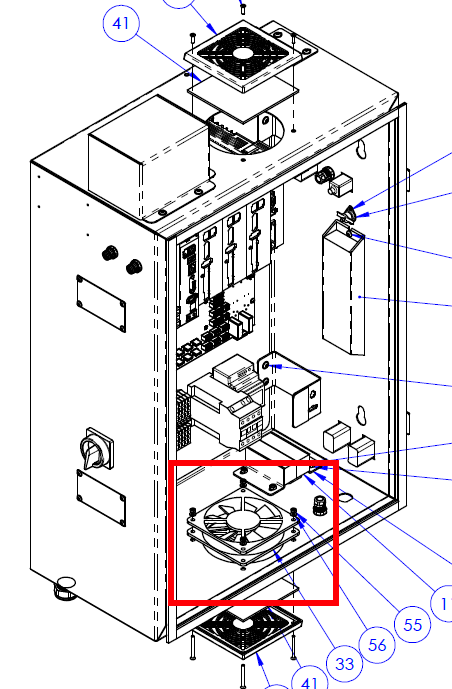

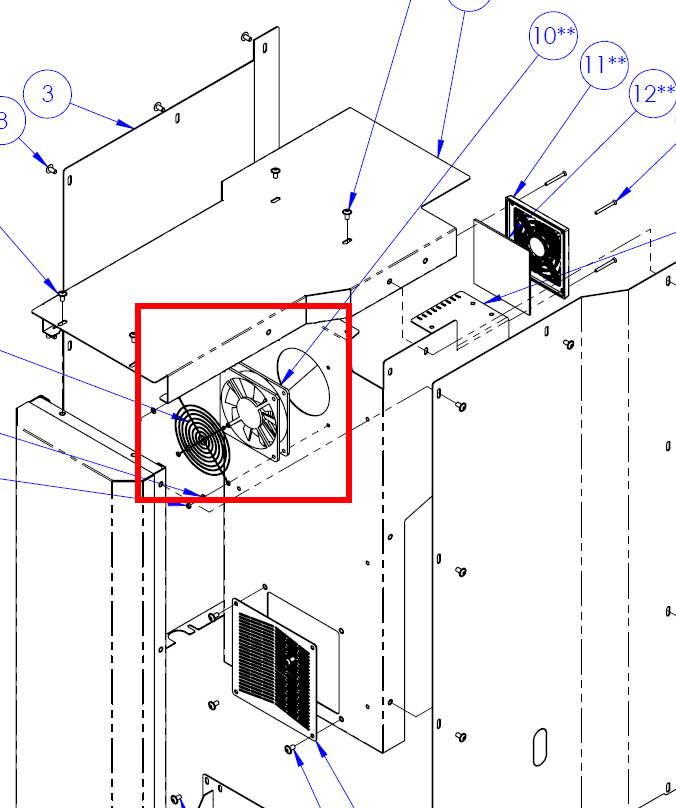

Check if Electrical Cabinet Fan (FAN1) and Spindle Motor Fan (FAN2) are running.

-

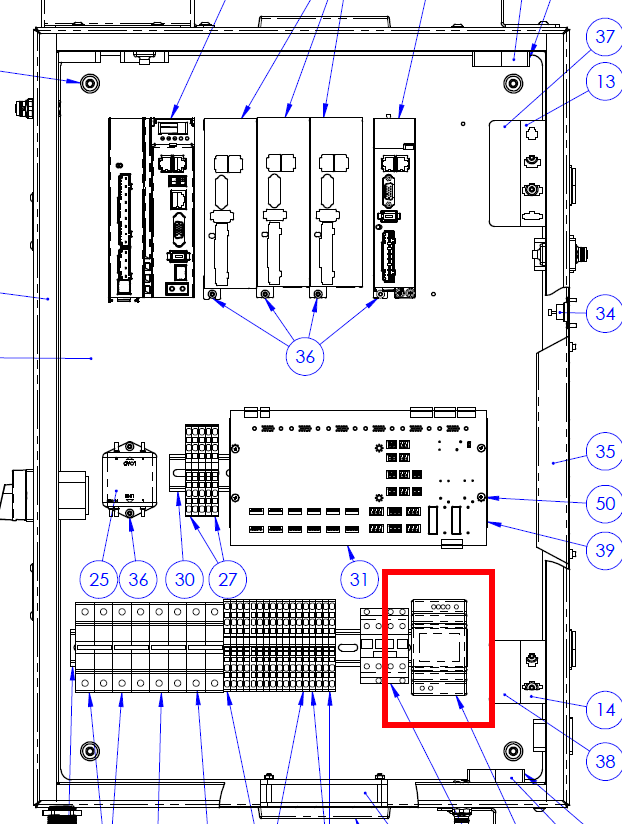

Check for DC OK LED on the PS1 DC power supply.

-

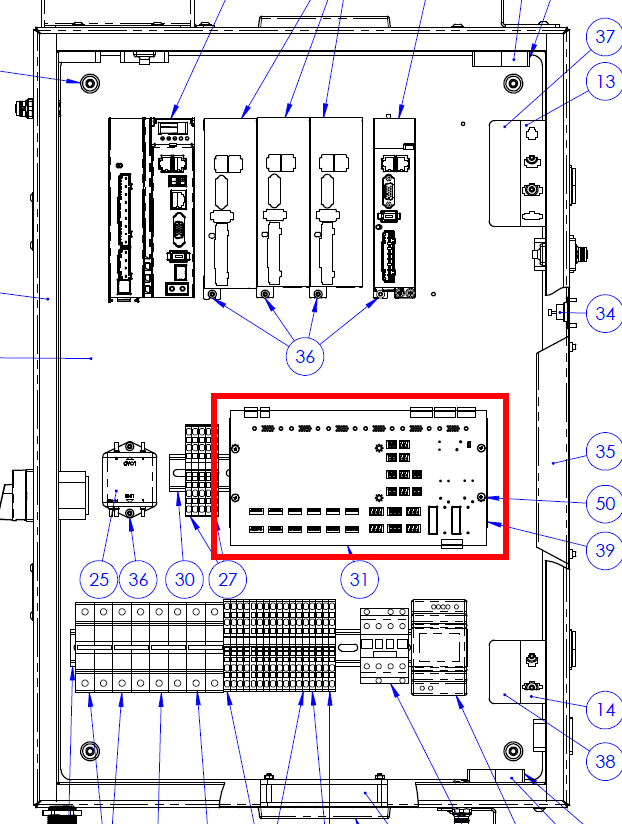

Check for Control Power (D37) LED on E1 Servo IO Breakout Board.

-

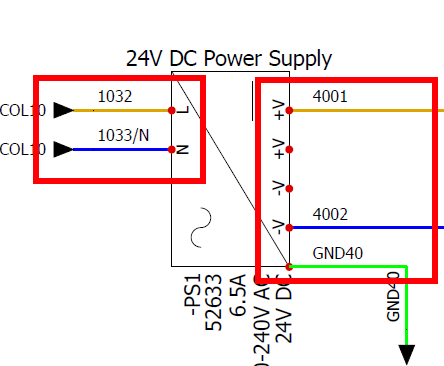

Measure for 208 Vac-240 Vac between wires 1032 and 1033/N at the PS1

DC power supply. -

Measure for 24 Vdc nominal between wires 4001 and 4002 at the PS1 DC

power supply.

Adjust the DC Power Supply PS1 Output Voltage

Reason: The DC power supply PS1 output voltage is too low.

-

Check if Electrical Cabinet Fan (FAN1) and Spindle Motor Fan (FAN2) are running. (See images above)

-

Check for DC OK LED on PS1 DC power supply. (See images above)

-

Measure for 208-240 Vac between wires 1032 and 1033/N at the PS1 DC power supply. (See images above)

-

Measure for 24 Vdc nominal between wires 4001 and 4002 at the PS1 DC power supply. (See images above)

-

If output voltage is less than 24 Vdc, adjust the output voltage using the +V ADJ trim potentiometer on the front of the PS1 DC power supply.

Reset Machine Circuit Breakers

Reason: The CB1, CB2, or CB4 circuit breaker tripped.

-

Examine the power cords and wires for damaged or exposed wires, and then reset the circuit breaker.

-

If needed, measure for 208-240 Vac between wires 1005 and 1006/N at the CB1 circuit breaker, between wires 1013 and 1014/N at the CB2 circuit breaker, and between wires 1020 and 1021/N at the CB4 circuit breaker.