Check Machine and Program Settings

Reason: Improper use of tool offset, work offset, or cutter compensation.

-

Examine the G-code programs. You must fully understand tool offsets, work offsets, and cutter compensation.

The most common cause of a perceived loss of a position is operator error.

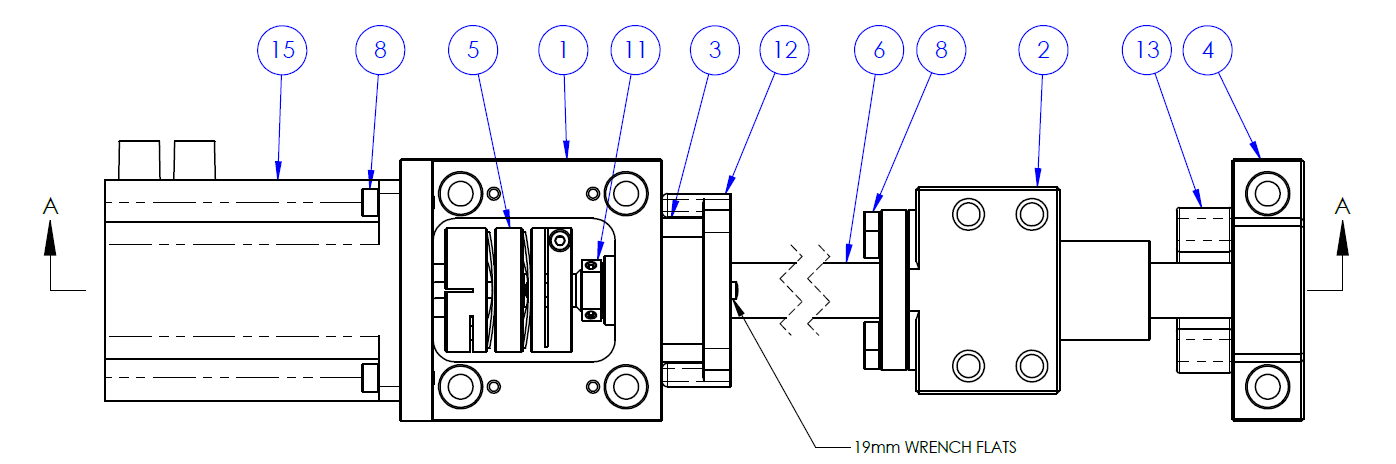

Inspect and Tighten Motor Coupler

Reason: The motor coupler is loose or cracked.

-

Examine the motor coupling.

You may find it useful to carefully run the axis with the cover removed. Make a paint line from the shaft through the coupling to the screw to examine if there’s any movement over time.

Inspect the Z-Axis Brake

Reason: The Z-Axis brake isn’t releasing.

-

Slowly jog the Z-axis: if the brake isn’t releasing, the Z-axis will usually move down properly, but won’t move up. A faulty Z-axis brake can over-torque and fault the Z-axis motor.

You should be able to hear the motor whenever you command the axis to move. Usually, the brake alone does not have the torque to cause a loss of motion. A condition like poor lubrication in combination with a defective Z brake are required to actually lose position.

Restart Controller

Reason: Controller or PathPilot problem.

-

Restart the controller and send the log file (from the logfiles directory) to Tormach Technical Support. Create a support ticket with Tormach Technical Support at http://tormach.com/how-to-submit-a-support-ticket for guidance on how to proceed.

For details of how to generate a Log Data file, see Generating a Log Data File in PathPilot

Check for Excessive Friction or Obstruction

Reason: There’s an obstruction or excessive friction, or there’s high load in the mechanical system.

-

Jog the axis axis and carefully observe the motion.

Typical mechanical issues include: an increase in friction due to lack of oil at the linear way surfaces or ball screw. They also come from excessive load on the system due to chips or debris, a sticking Z-Axis brake or an end-of-travel bumper wedged against the motor mount casting.

Excessive chip and debris, or a lack of lubrication can also increase the load applied by the way covers. When MQL coolant is used, the way covers' panels should be lubricated with a light oil to reduce frication due to their seals.