Background

The idea of providing power to your machine seems simple: just plug it in. In reality, there are a number of other components used in order to provide power appropriately safety for you and the machine, including (but not limited to):

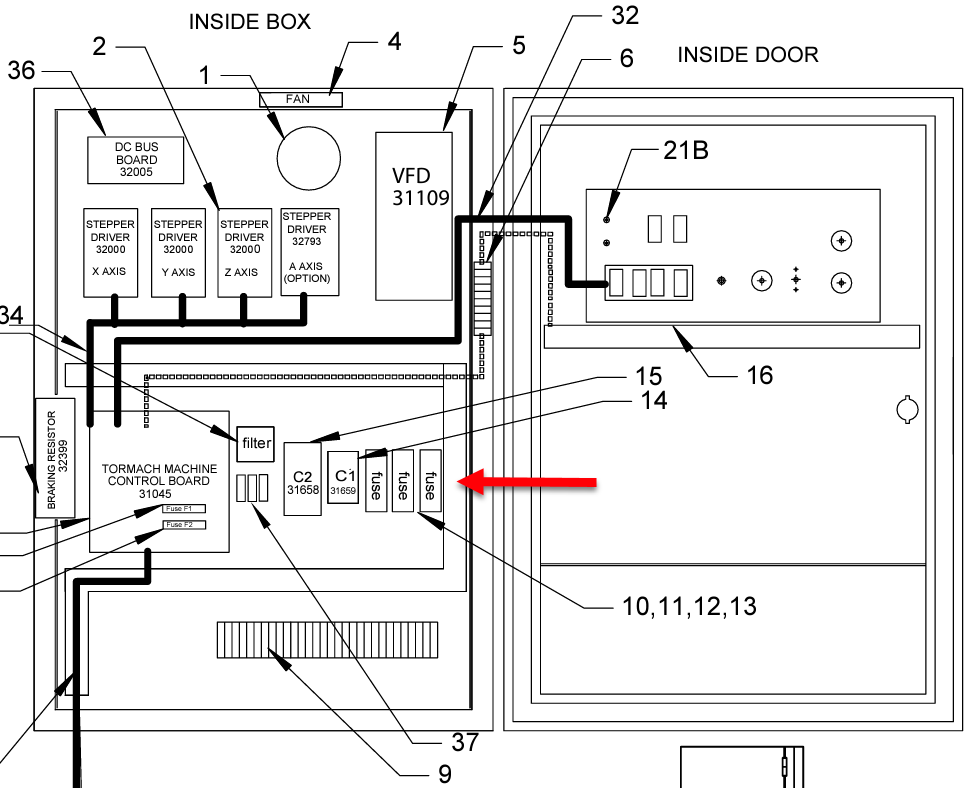

-

The main disconnect switch

-

Fuses and/or circuit breakers

-

Emergency stop switch/button

-

Separate latching circuits for the spindle and rest of the machine

-

Transformers, which change the electricity to the appropriate value

Even with all of these components, you can systematically locate nearly any problem with just a multimeter.

Tools

-

Multimeter

Twist Out the Emergency Stop Button

Reason: The Emergency Stop button is pushed in.

-

Twist out the Emergency Stop button and press the Reset button.

The Reset button doesn't illuminate until after you:

-

Twist out the Emergency Stop button.

-

Press the Reset button.

Reset the Building’s Mains Breaker

Reason: The shop or building’s mains breaker is turned off.

-

Examine the building’s breaker. If it’s not already on, turn it on.

-

Using a digital multimeter, measure to inspect and verify that you have power at the outlet.

Inspect the Power Entering the Machine

Reason: The Main Disconnect switch is in the Off position.

-

Examine the Main Disconnect switch. If it’s not already in the On position, turn it on and try to take your machine out of reset.

-

Measure the voltage coming out of your Main Disconnect switch.

-

Identify the wires as indicated in the table.

-

If you measure the correct Vac, continue.

-

If you do not any Vac, you either have a loose wire or a faulty Main Disconnect switch.

-

|

Machine |

Wires |

Measure for… |

|---|---|---|

|

PCNC 770 |

91 and 100 |

120 Vac nominal |

Check the FU1, FU3 and FU6 Fuses

Reason: Fuse is blown.

-

Identify your machines main fuses.

-

Power down the machine, and remove both fuses.

-

Check both fuses using the following process: Checking a Fuse on a Tormach Machine

-

If any fuse is blown, replace it.